DD15 Coolant System: Diagram, Issues, and Tips

The DD15 coolant system is the lifeblood of your powerful engine, diligently working to maintain optimal operating temperatures and prevent costly overheating. At VCCarTool, we understand the critical role a properly functioning engine cooling system plays in the performance and longevity of your vehicles, which is why we’re here to provide you with comprehensive insights and the finest tools to keep your DD15 running cool and efficiently.

Dive in to explore the intricacies of this vital system and discover how VCCarTool can empower you to conquer any cooling challenge. Understanding your engine’s heat exchange system, antifreeze system, and overall thermal management system is key to proactive maintenance.

1. Decoding the DD15 Coolant System: An Essential Overview

The Detroit Diesel DD15 engine is a powerhouse known for its efficiency and durability, and at the heart of its reliable operation lies a sophisticated DD15 cooling system. This intricate network of components ensures that the engine maintains its ideal temperature range, crucial for peak performance, fuel efficiency, and longevity. The DD15 coolant circuit, also referred to as the DD15 engine coolant loop, meticulously circulates coolant to absorb heat from engine parts and dissipate it through the radiator. A well-maintained DD15 heat exchange system is essential for preventing overheating and the associated engine damage.

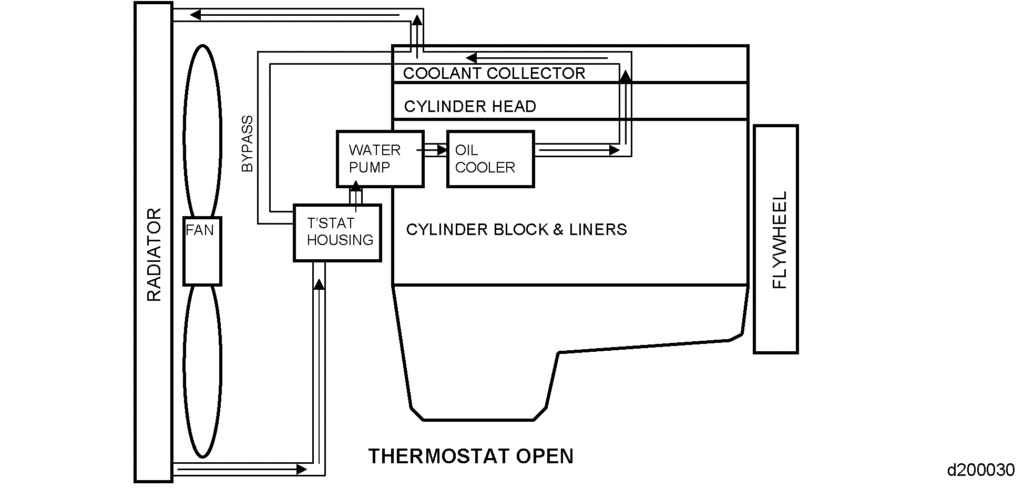

DD Coolant Flow thermostat open

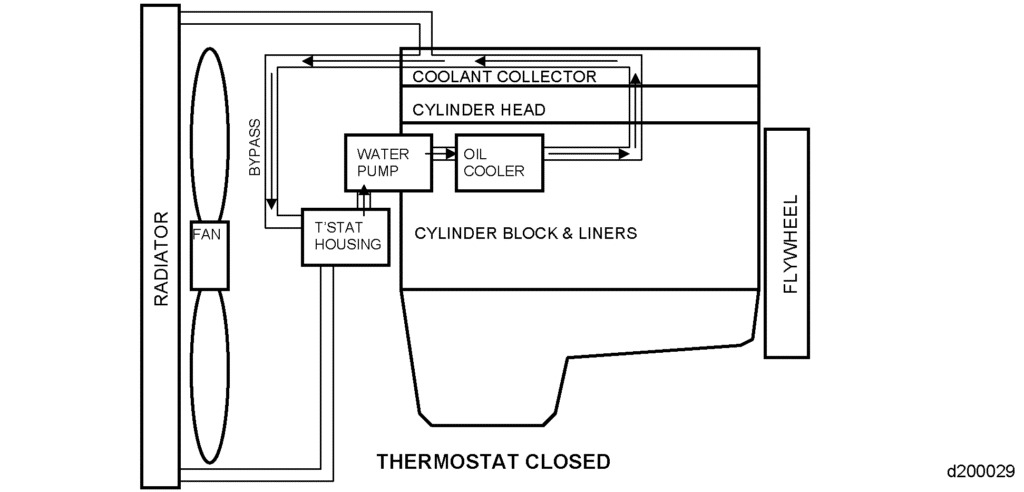

DD Coolant Flow thermostat closed

1.1 The Vital Role of Engine Cooling

Imagine the intense friction and combustion happening within your engine. Without an effective DD15 Engine Cooling system, this generated heat would quickly lead to catastrophic failure. The primary functions of the coolant system include:

-

Temperature Regulation: Maintaining the engine within its optimal temperature range (typically around 195-210°F or 90-99°C) for efficient combustion and reduced wear. (Source: Engineering Toolbox, “Engine Operating Temperatures”).

-

Heat Dissipation: Transferring excess heat away from critical engine components like the cylinder head and engine block to the radiator for cooling.

-

Corrosion Protection: Modern coolants contain additives that prevent rust and corrosion within the cooling system.

-

Freeze Protection: Ensuring the coolant doesn’t freeze in cold weather, which could cause significant damage to engine components.

-

Boiling Point Elevation: Raising the boiling point of the coolant to prevent it from vaporizing under high operating temperatures.

1.2 Key Components of the DD15 Coolant Network

The DD15 Radiator System comprises several crucial parts working in harmony:

| Component | Function |

| Coolant Pump | Circulates coolant throughout the engine and radiator. |

| Radiator | Dissipates heat from the coolant to the atmosphere. |

| Thermostat | Regulates coolant flow to maintain optimal engine operating temperature. |

| Coolant Hoses | Carry coolant between the engine, radiator, and other components. |

| Expansion Tank | Accommodates the expansion and contraction of coolant volume. |

| Radiator Cap | Maintains pressure within the system and prevents coolant boiling. |

| Coolant Temperature Sensor | Monitors the engine coolant temperature and sends data to the ECU. |

2. Navigating the DD15 Coolant Flow: A Detailed Look

Understanding the precise path of coolant within your DD15 is invaluable for effective troubleshooting. Here’s a simplified overview of the DD15 coolant flow:

-

Coolant Circulation Begins: The coolant pump, driven by the engine, draws coolant from the lower radiator hose or the expansion tank.

-

Engine Block Cooling: The coolant flows through passages in the engine block and cylinder head, absorbing heat generated by combustion.

-

Thermostat Regulation: Depending on the engine temperature, the thermostat either restricts flow to the radiator (when cold, allowing the engine to warm up quickly) or allows coolant to flow to the radiator for cooling (once the operating temperature is reached).

-

Heat Exchange in the Radiator: Hot coolant enters the top of the radiator and flows through its core, where heat is transferred to the air passing through the fins. The cooled coolant exits the bottom of the radiator.

-

Return to the Engine: The cooled coolant returns to the engine via the lower radiator hose, ready to repeat the cycle.

-

Expansion Tank Management: As the coolant heats up, it expands. The expansion tank provides a space for this extra volume, preventing pressure buildup. When the engine cools, coolant is drawn back into the system from the expansion tank.

For a detailed visual representation, a DD15 coolant system diagram is an indispensable resource, often available in your engine’s service manual or through reputable online sources.

3. Common DD15 Coolant System Issues: Identification and Resolution

Even with diligent maintenance, the DD15 cooling system can encounter problems. Recognizing these issues early can save you significant time and money.

3.1 Overheating: A Critical Concern

One of the most concerning DD15 engine temperature control problems is overheating. This can be caused by several factors:

-

Low Coolant Level: Due to leaks or insufficient filling.

-

Faulty Thermostat: Stuck closed, preventing coolant flow to the radiator.

-

Clogged Radiator: Internal or external blockages hindering heat transfer.

-

Failing Water Pump: Insufficient coolant circulation.

-

Air Pockets in the System: Trapped air restricting coolant flow.

-

Leaking Hoses or Connections: Resulting in coolant loss and reduced system pressure.

Troubleshooting Overheating:

-

Check Coolant Level: Ensure it’s within the recommended range in the expansion tank.

-

Inspect for Leaks: Look for any visible coolant leaks around hoses, connections, the radiator, and the water pump.

-

Examine the Radiator: Check for debris blocking the fins and ensure proper airflow.

-

Consider the Thermostat: A stuck thermostat can be diagnosed with a temperature test on the upper and lower radiator hoses after the engine has warmed up. If the upper hose is hot and the lower is cool, the thermostat might be the culprit.

-

Listen for Water Pump Issues: Unusual noises or a lack of coolant circulation can indicate a failing pump.

3.2 Coolant Leaks: Pinpointing the Source

Identifying the source of a DD15 Antifreeze System leak is crucial for effective repair. Common leak locations include:

-

Hoses: Especially near clamps or where they rub against other components.

-

Radiator: Look for wet spots or stains on the radiator core or tanks.

-

Water Pump: Leaks may be visible around the pump’s weep hole.

-

Thermostat Housing: Corrosion or a faulty gasket can cause leaks.

-

Head Gasket: Often accompanied by other symptoms like white smoke from the exhaust or coolant in the oil.

Addressing Coolant Leaks:

-

Visual Inspection: Carefully examine all components of the cooling system for signs of leakage.

-

Pressure Testing: A cooling system pressure tester can help identify hard-to-find leaks by pressurizing the system.

-

Hose and Clamp Check: Ensure hoses are in good condition and clamps are tight. Replace any damaged hoses.

3.3 Coolant Contamination: Maintaining Purity

Contaminants in the DD15 Engine Coolant Loop can reduce its effectiveness and damage system components. Common contaminants include:

-

Oil: Often indicates a failing oil cooler or head gasket.

-

Rust and Scale: Result from using inadequate coolant or infrequent coolant flushes.

-

Debris: Can enter the system through an open radiator or expansion tank.

Dealing with Coolant Contamination:

-

Visual Inspection: Check the coolant’s appearance. Discoloration or the presence of oil slicks indicates contamination.

-

Coolant Flush: A thorough coolant flush is necessary to remove contaminants.

-

Identify and Repair the Source: If oil is present, diagnose and repair the oil cooler or head gasket issue.

4. The Right Fluid for the Job: Recommended Coolant Type for DD15 Engine

Using the correct coolant is paramount for the health of your DD15. Detroit Diesel typically recommends specific formulations that meet their requirements for corrosion protection and material compatibility. Always consult your DD15 engine’s service manual for the precise recommended coolant type and specifications. Generally, heavy-duty, low-silicate, ethylene glycol-based coolants with the appropriate additives are required. Using the wrong type of coolant can lead to:

-

Reduced Corrosion Protection: Damaging internal cooling system components.

-

Sludge Buildup: Restricting coolant flow and reducing heat transfer.

-

Seal and Hose Degradation: Leading to leaks.

5. Maintaining Peak Performance: DD15 Coolant System Maintenance

Proactive maintenance is the key to a reliable DD15 cooling system. Here are some essential maintenance practices:

-

Regular Coolant Level Checks: Monitor the coolant level in the expansion tank and top up as needed with the correct coolant mixture (usually a 50/50 mix of coolant and distilled water).

-

Scheduled Coolant Flushes: Follow the manufacturer’s recommended intervals (typically every 3-5 years or a specific mileage) for flushing and replacing the coolant. This removes old coolant, contaminants, and replenishes the corrosion inhibitors.

-

Hose and Belt Inspections: Regularly inspect coolant hoses for cracks, swelling, or leaks. Check the condition and tension of the water pump drive belt.

-

Radiator Cap Testing: Ensure the radiator cap is holding the correct pressure. A faulty cap can lead to coolant loss and a lower boiling point.

-

System Pressure Testing: Periodically pressure test the cooling system to check for leaks that may not be immediately apparent.

6. Empowering Your Maintenance: VCCarTool – Your Partner in Cooling System Care

At VCCarTool, we understand the demands placed on your DD15 engine and the critical role of its cooling system. That’s why we offer a comprehensive range of high-quality diagnostic tools and equipment designed to help you maintain and troubleshoot your DD15 coolant system with confidence.

6.1 Advanced Diagnostic Tools for Efficient Troubleshooting

Our selection includes advanced diagnostic scanners that can provide real-time data on coolant temperature, water pump speed, and other vital parameters, allowing you to pinpoint potential issues before they escalate. These tools empower both young auto mechanics looking to invest in modern technology and experienced auto mechanics seeking to enhance their diagnostic capabilities. Garage owners and managers will appreciate how these tools improve efficiency, reduce repair time, and ultimately increase profitability.

6.2 Quality Tools for Every Cooling System Task

From coolant pressure testers and refractometers (for checking coolant freeze point) to specialized hose clamp pliers and coolant filling tools, VCCarTool provides the reliable equipment you need to perform thorough cooling system maintenance and repairs. Our tools are built to last, catering to the needs of both individual technicians and busy auto repair shops.

6.3 Expertise and Support You Can Trust

At VCCarTool, we’re more than just a supplier of tools. Our team comprises experienced professionals who understand the challenges you face. We’re committed to providing you with the knowledge and support you need to keep your DD15 engines running optimally.

7. Benefits of Choosing VCCarTool for Your Cooling System Needs

Investing in high-quality tools from VCCarTool offers numerous advantages:

-

Improved Work Efficiency: Accurate diagnostics and reliable tools streamline the repair process, saving you valuable time.

-

Reduced Repair Time: Quickly identify and resolve cooling system issues, minimizing vehicle downtime.

-

Increased Accuracy and Safety: Our tools are designed for precision and ease of use, ensuring safe and effective repairs.

-

Cost Savings for Your Customers: Efficient diagnostics and proper maintenance can prevent costly engine damage for your clients.

-

Enhanced Garage Reputation: Providing high-quality service with advanced tools builds trust and customer loyalty.

-

Increased Revenue and Profitability: Faster turnaround times and accurate repairs contribute to a more profitable operation.

Ready to take control of your DD15 coolant system maintenance and repairs? Visit vccartool.com today or contact us via WhatsApp at +1 (901) 414 – 1927 to explore our wide range of diagnostic tools and equipment. Our knowledgeable team is ready to assist you in selecting the perfect tools to meet your specific needs and elevate your service capabilities. Don’t let cooling system issues slow you down – partner with VCCarTool for reliable solutions and peak engine performance.

By choosing VCCarTool, you’re not just buying tools; you’re investing in the reliability and longevity of your vehicles and the success of your business.

Contact us now to experience the VCCarTool advantage. Our commitment is to provide you with the highest quality equipment and unparalleled support, ensuring your DD15 engines stay cool and perform at their best. Reach out today and let us help you enhance your auto repair capabilities.