What is Active cornering enhancement?

Active Cornering Enhancement (ACE) is a cutting-edge technology that enhances vehicle stability and handling, particularly during sharp turns and dynamic driving conditions. At VCCarTool, we recognize the importance of systems like active cornering enhancement in improving safety and ride comfort. In this article, we break down how ACE works, its key benefits, and why it’s becoming a standard in high-performance and luxury vehicles. Whether you’re a technician or an automotive enthusiast, this guide offers valuable insights backed by VCCarTool’s expertise.

What Is Active Cornering Enhancement?

Active Cornering Enhancement (ACE) is an advanced vehicle stability system designed to improve handling, especially when driving through corners at higher speeds. It works by reducing body roll—the natural leaning of a vehicle’s body when turning—thereby enhancing both safety and comfort for the driver and passengers.

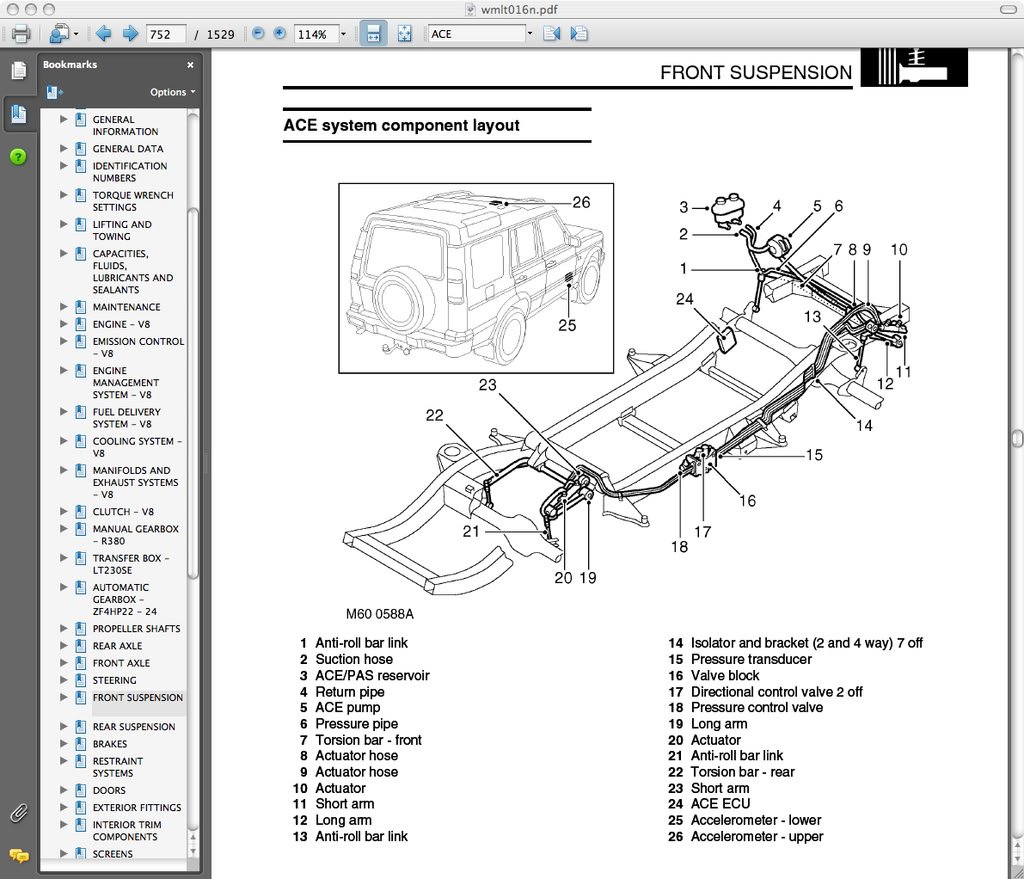

The system uses a series of sensors and hydraulic actuators to monitor and control the vehicle’s suspension in real time. When a cornering maneuver is detected, ACE adjusts the suspension response to maintain a level body posture, ensuring the tires stay in optimal contact with the road.

Originally developed by manufacturers like Land Rover, ACE is typically found in luxury SUVs and performance vehicles. By actively managing the forces acting on the car during turns, active cornering enhancement helps prevent rollover, improves steering precision, and gives the driver more confidence in challenging driving conditions.

At VCCarTool, we specialize in providing support, diagnostics, and programming services for vehicles equipped with systems like ACE.

Land Rover Ace (active cornering enhancement)

How Does Active Cornering Enhancement (ACE) Work?

Active Cornering Enhancement (ACE) functions by continuously monitoring the vehicle’s behavior during cornering and dynamically adjusting the suspension system to maintain stability

At the heart of ACE are a network of sensors and an Electronic Control Unit (ECU). These sensors detect lateral acceleration, steering angle, vehicle speed, and yaw rate as the vehicle enters a turn. Normally, these forces would cause the body of the vehicle to roll outward, affecting handling and passenger comfort.

When such movement is detected, the ECU commands hydraulic actuators or electromechanical components within the suspension to counteract the roll. These components apply force in the opposite direction of the body’s lean, keeping the chassis more level. The result is sharper handling, increased traction, and greater passenger safety during high-speed cornering or evasive maneuvers.

ACE operates in real-time, meaning adjustments are made within milliseconds of detecting movement—far faster than a human driver could react. This makes it especially useful in SUVs and taller vehicles where body roll is more pronounced.

At VCCarTool, we offer expert diagnostics and support for ACE systems to ensure they continue to perform optimally under all driving conditions.

Benefits of Active Cornering Enhancement (ACE)

Active Cornering Enhancement (ACE) offers a range of advantages that improve both driving dynamics and overall vehicle performance. Here are the key benefits:

Improved Comfort

ACE minimizes body roll during cornering, which significantly reduces the sensation of being pushed sideways. Passengers enjoy a smoother, more stable ride—especially beneficial during long drive or sharp maneuvers.

Enhanced Stability

By actively managing lateral forces, ACE keeps the vehicle more grounded in corners. This helps prevent loss of grip, especially in high-speed turns or emergency situations, contributing to overall driving safety.

Better Handling

With reduced body movement, steering response becomes sharper and more predictable. This makes it easier for drivers to control the vehicle, improving confidence behind the wheel.

Extended Lifespan of Vehicle Components

Because ACE reduces the stress placed on suspension components and tires during aggressive cornering, it can help lower wear and tear. Over time, this can lead to longer-lasting parts and fewer maintenance costs.

At VCCarTool, we specialize in diagnosing, maintaining, and optimizing ACE systems to ensure you get the full benefit of this advanced technology in your vehicle.

The Evolution of ACE

Since its debut, ACE has evolved from hydraulically actuated systems to more sophisticated, electronically controlled ones. Early versions used mechanical valves, while modern iterations integrate AI-driven algorithms that anticipate vehicle behavior. As connected car technologies and electric architectures advance, expect ACE to become smarter and more predictive in its adjustments.

Understanding the ACE Warning Light

An important part of ACE is the system’s ability to inform the driver about potential issues. This is where the ACE light comes into play. Here’s what it means:

- Amber (Solid): Indicates a system fault. Performance may be limited, but it’s not dangerous. Drive with caution and schedule a diagnostic check.

- Red (Flashing/Steady): Signifies a critical error—such as low fluid pressure or a sensor failure—that could affect handling. Stop the vehicle and seek professional assistance immediately.

Common causes include:

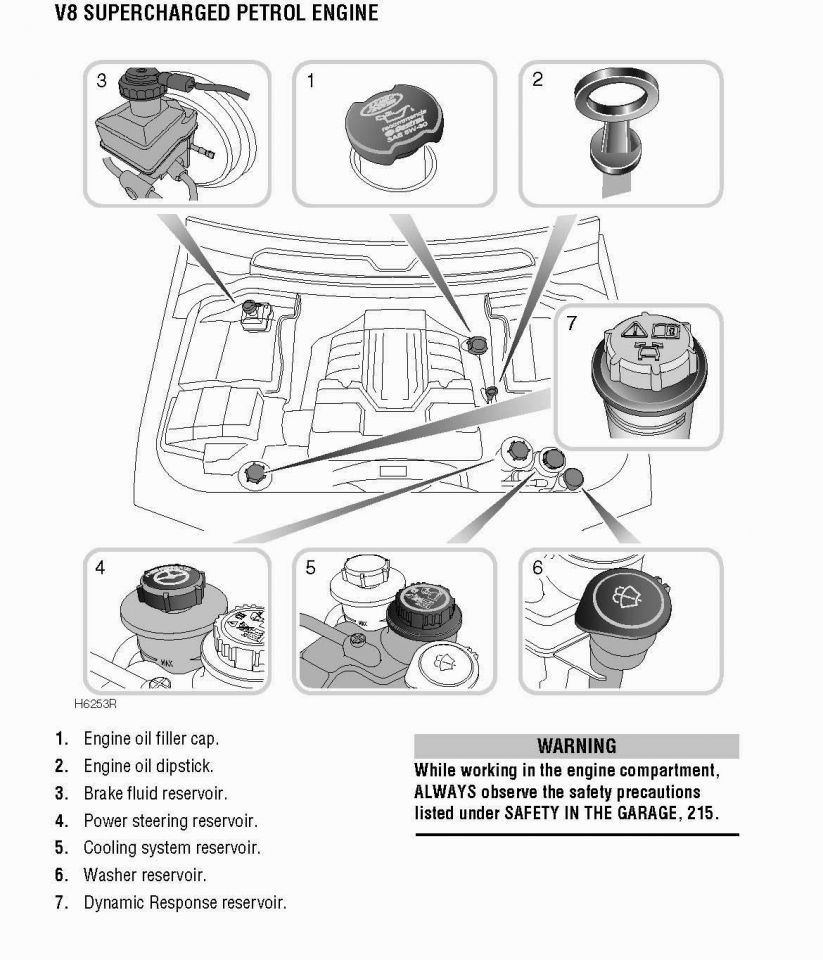

- Low hydraulic fluid

- Faulty sensors

- Poor electrical connections

- Failing actuators

Often, reseating connectors or topping off fluid may solve the problem. However, persistent alerts should always be addressed with proper diagnostic tools.

Tools and Services for ACE Diagnostics

To properly inspect or repair an ACE system, professional-grade equipment is required. At VCCarTool, we provide access to:

- Advanced diagnostic tools for Land Rover, Range Rover, and Jaguar

- Online programming and calibration services

- Remote technical support for suspension systems

- Component-level diagnostics and repair guidance

Whether you’re a technician or an enthusiast, having the right interface—such as the Pathfinder or SDD software with a compatible VCI—is crucial for accurate troubleshooting and reset procedures.

Final Thoughts

Active Cornering Enhancement exemplifies the future of intelligent suspension technology. It doesn’t just improve handling; it redefines comfort and safety in motion. As automotive technology progresses, systems like ACE will continue to evolve, offering even greater control, smarter diagnostics, and integration with autonomous driving features.

For drivers and repair professionals alike, understanding ACE is not only useful—it’s essential.

Need help with ACE diagnostics or coding? Contact VCCarTool via WhatsApp: +1 (901) 414-1927 to get expert guidance, diagnostic packages, and remote support today.