Daimler Truck Downloads: Diagnostics, Programming Software

Daimler Truck, a global leader in commercial vehicles, faces the challenges of diagnostics, programming, and error code resolution. This comprehensive guide dives deep into the world of Daimler Truck diagnostics and programming, offering expert insights, software solutions, and efficient download assistance to keep you ahead in the game. Discover how VCCarTool can help you streamline your operations with the right software and support. Uncover LSI keywords like “truck diagnostic software,” “Daimler fault code programming,” and “commercial vehicle ECU programming” within this guide.

Click the Daimler Truck link or contact us via WhatsApp: +1 (901) 414 – 1927 for download, support FREE Mercedes Daimler Truck Software

1. Understanding the Daimler Truck Landscape

Daimler Truck is a behemoth in the commercial vehicle industry, encompassing well-known brands like Freightliner and Western Star. These trucks are the backbone of countless businesses, transporting goods across vast distances. However, with advanced technology comes increased complexity. Modern Daimler Trucks rely on sophisticated electronic control units (ECUs) and intricate software systems. When things go wrong, quickly diagnosing and repairing these vehicles is crucial.

1.1 The Growing Complexity of Modern Trucks

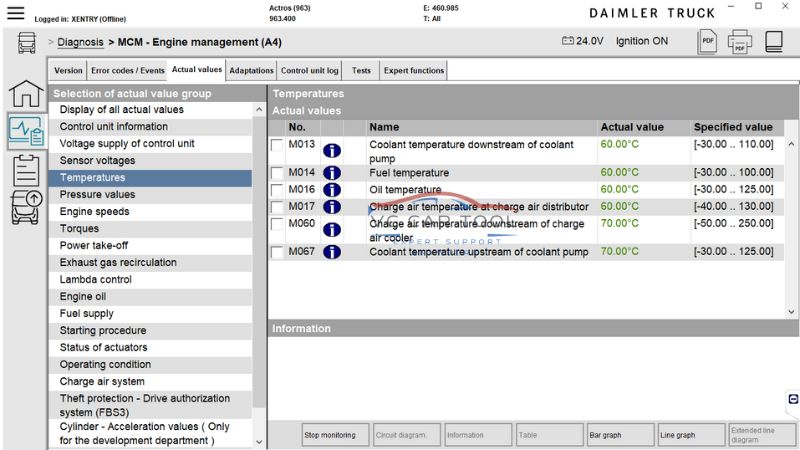

Gone are the days of simple mechanical fixes. Today’s Daimler Trucks are rolling computers, packed with sensors, actuators, and interconnected systems. This complexity demands specialized knowledge and tools for effective diagnostics and repair.

1.2 The Importance of Efficient Diagnostics and Programming

Downtime is costly for any trucking operation. Efficient diagnostics and programming minimize downtime, ensuring vehicles are back on the road quickly and safely. This requires technicians to have access to the right software, diagnostic tools, and expert support.

2. Key Diagnostic and Programming Challenges

Technicians working on Daimler Trucks face a unique set of challenges. Understanding these challenges is the first step towards overcoming them.

2.1 Identifying and Interpreting Error Codes

Modern trucks generate a multitude of error codes, each pointing to a potential problem. Deciphering these codes and understanding their root cause requires specialized diagnostic software and a deep understanding of the vehicle’s systems.

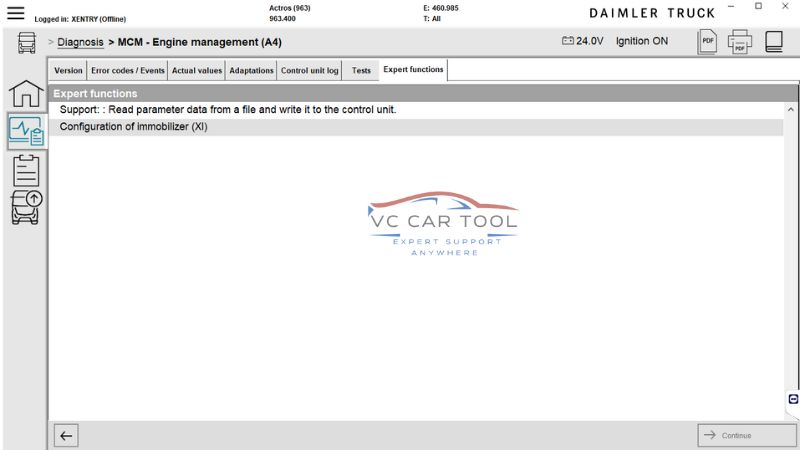

2.2 Navigating Complex ECU Programming Procedures

ECU programming is often necessary after replacing a component or updating the vehicle’s software. These procedures can be complex and require specific software and knowledge to avoid damaging the ECU.

2.3 Keeping Up with Ever-Evolving Technology

The automotive industry is constantly evolving, with new technologies and software updates being released regularly. Technicians need to stay up-to-date with these changes to effectively diagnose and repair modern Daimler Trucks.

3. Essential Software Solutions for Daimler Truck

Having the right software is paramount for efficient Daimler Truck diagnostics and programming. Here’s a look at some essential software solutions:

3.1 Daimler Diagnostic Software (e.g., DiagnosticLink)

Daimler’s proprietary diagnostic software, such as DiagnosticLink, provides comprehensive diagnostic capabilities. It allows technicians to read error codes, view live data, perform diagnostic tests, and program ECUs.

3.2 ECU Programming Software

ECU programming software is essential for updating or re-flashing the vehicle’s ECUs. This software often requires a specific interface and access to Daimler’s servers.

3.3 Aftermarket Diagnostic Tools and Software

Several aftermarket diagnostic tools and software solutions offer compatibility with Daimler Trucks. These tools can provide a cost-effective alternative to the OEM software.

Considerations when choosing software:

| Feature | OEM Software (e.g., DiagnosticLink) | Aftermarket Software |

|---|---|---|

| Coverage | Comprehensive | Varies |

| Functionality | Full | May be limited |

| Cost | Higher | Lower |

| Updates | Regular | May be less frequent |

| Support | Direct from Daimler | Varies by vendor |

4. VCCarTool: Your Partner for Daimler Truck Solutions

VCCarTool understands the challenges faced by technicians working on Daimler Trucks. We offer a range of software solutions, download assistance, and expert support to help you streamline your operations.

4.1 Streamlined Software Downloads

We provide quick and easy access to the software you need, saving you valuable time and effort. Our download process is designed to be efficient and hassle-free. If you experience any issues, contact VCCarTool via WhatsApp +1 (901) 414 – 1927 for immediate assistance.

4.2 Expert Support and Guidance

Our team of experienced technicians is available to provide expert support and guidance. We can help you troubleshoot diagnostic problems, navigate complex programming procedures, and choose the right software for your needs.

4.3 Reliable and Secure Software

We ensure that all the software we offer is reliable, secure, and free from viruses. You can trust that you are downloading safe and effective tools.

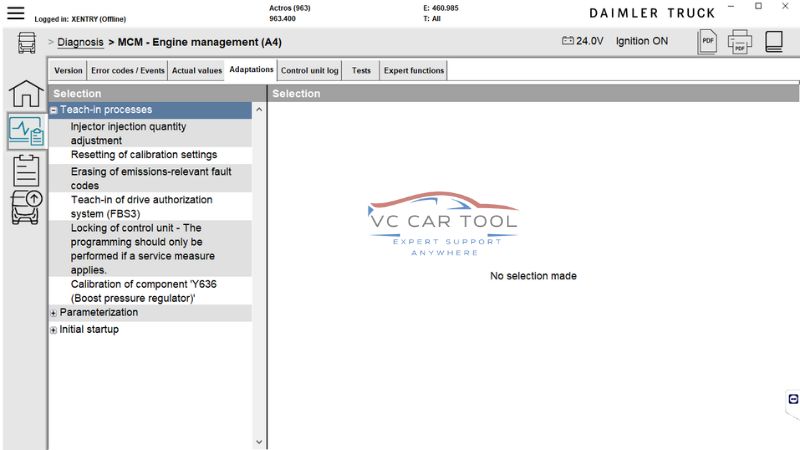

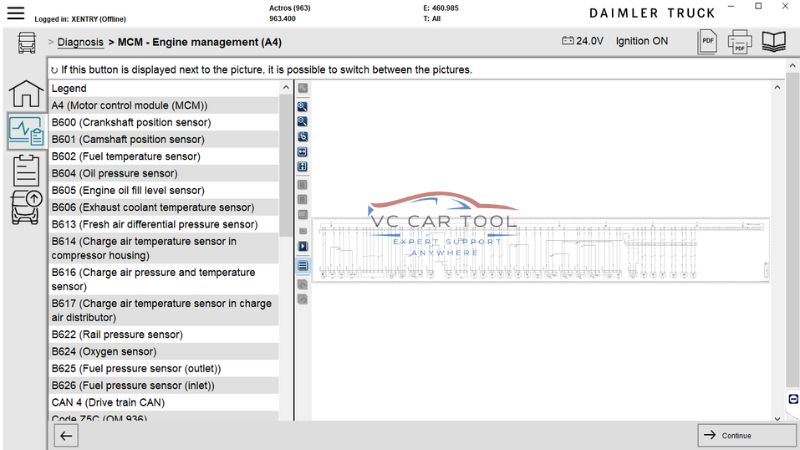

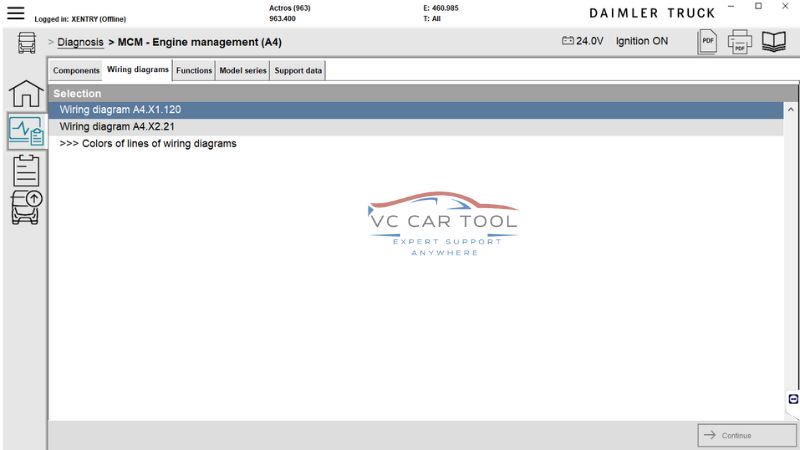

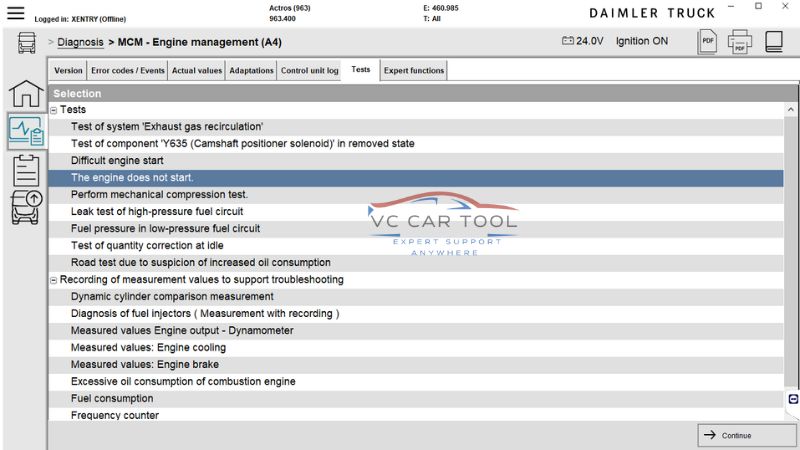

5. Step-by-Step Guide to Daimler Truck Diagnostics

Let’s walk through a typical Daimler Truck diagnostic process.

5.1 Connecting to the Vehicle

- Connect the diagnostic tool to the vehicle’s diagnostic port (usually located under the dashboard).

- Ensure the vehicle’s ignition is turned on.

- Launch the diagnostic software on your computer or tablet.

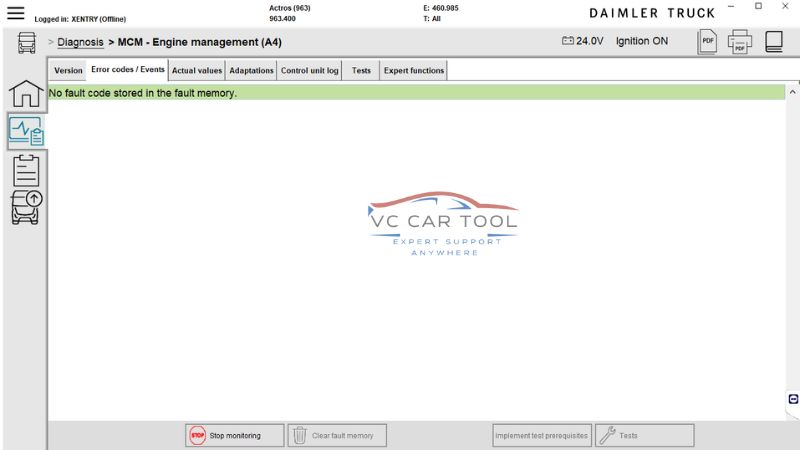

5.2 Reading Error Codes

- Select the appropriate vehicle model and year in the diagnostic software.

- Initiate a diagnostic scan to read any stored error codes.

- Record all error codes and their descriptions.

5.3 Interpreting Error Codes

- Consult the vehicle’s service manual or online resources to understand the meaning of each error code.

- Identify the potential causes of the error.

- Prioritize the most likely causes based on the error code and vehicle’s symptoms.

5.4 Performing Diagnostic Tests

- Use the diagnostic software to perform specific tests related to the error codes.

- These tests may include checking sensor readings, activating actuators, and monitoring system performance.

- Analyze the test results to pinpoint the source of the problem.

5.5 Repairing the Fault

- Based on the diagnostic findings, repair or replace the faulty component.

- Ensure the new component is properly installed and calibrated.

5.6 Clearing Error Codes and Verifying Repair

- After completing the repair, clear the error codes using the diagnostic software.

- Perform another diagnostic scan to ensure no new error codes have appeared.

- Test drive the vehicle to verify that the problem has been resolved.

6. Best Practices for Daimler Truck Programming

ECU programming requires careful attention to detail. Here are some best practices to follow:

6.1 Ensuring a Stable Power Supply

A stable power supply is crucial during ECU programming. Use a battery maintainer to prevent voltage fluctuations that could damage the ECU.

6.2 Using the Correct Software and Firmware

Always use the correct software and firmware versions for the specific vehicle and ECU. Incorrect versions can lead to compatibility issues or ECU failure.

6.3 Following the Manufacturer’s Instructions

Carefully follow the manufacturer’s instructions for the programming procedure. Deviating from these instructions can result in errors or damage to the ECU.

6.4 Backing Up Existing Data

Before programming an ECU, back up the existing data. This allows you to restore the original configuration if something goes wrong.

6.5 Verifying Programming Success

After programming, verify that the procedure was successful by checking for error codes and testing the functionality of the ECU.

7. Common Daimler Truck Error Codes and Solutions

Here are some common Daimler Truck error codes and potential solutions:

| Error Code | Description | Potential Solutions |

|---|---|---|

| SPN 100 FMI 2 | Engine Oil Pressure Low | Check oil level, inspect oil pump, check oil pressure sensor. |

| SPN 157 FMI 5 | Injector Circuit Open/Shorted | Inspect injector wiring, test injector resistance, replace faulty injector. |

| SPN 629 FMI 9 | Aftertreatment Diesel Particulate Filter | Perform a forced regeneration, inspect DPF for damage, check differential pressure sensor. |

| SPN 1081 FMI 9 | SCR System Malfunction | Check DEF level, inspect DEF injector, check NOx sensors, verify SCR catalyst performance. |

| SPN 3251 FMI 12 | Exhaust Gas Recirculation (EGR) Valve | Inspect EGR valve for carbon buildup, clean or replace EGR valve, check EGR cooler. |

8. The Future of Daimler Truck Diagnostics and Programming

The future of Daimler Truck diagnostics and programming is likely to be shaped by several key trends:

8.1 Increased Use of Remote Diagnostics

Remote diagnostics will become increasingly common, allowing technicians to diagnose and repair vehicles remotely. This can reduce downtime and improve efficiency.

8.2 Predictive Maintenance

Predictive maintenance uses data analysis to identify potential problems before they occur. This allows technicians to proactively address issues, preventing breakdowns and reducing maintenance costs.

8.3 Over-the-Air (OTA) Updates

OTA updates will become more prevalent, allowing Daimler to update vehicle software remotely. This eliminates the need for physical visits to the shop for software updates.

8.4 Integration with Telematics Systems

Diagnostic and programming tools will become more integrated with telematics systems, providing real-time data on vehicle performance and health. This will enable more efficient diagnostics and maintenance.

9. Choosing the Right Diagnostic Tool for Your Needs

Selecting the correct diagnostic tool is paramount. Evaluate factors like coverage, capabilities, updates, and support. Consider your budget and the specific needs of your operation.

Factors to Consider:

- Vehicle Coverage: Does the tool support the specific Daimler Truck models you work on?

- Functionality: Does it offer the diagnostic and programming features you need?

- Updates: How often are software updates released, and how much do they cost?

- Support: What kind of technical support is available from the vendor?

- Cost: How does the cost of the tool compare to its features and capabilities?

10. Tips for Saving Time and Money on Daimler Truck Repairs

Efficient diagnostics and programming can save significant time and money. Here are some practical tips:

- Invest in Proper Training: Ensure your technicians are properly trained on Daimler Truck diagnostic and programming procedures.

- Keep Software Up-to-Date: Regularly update your diagnostic software to ensure you have the latest features and bug fixes.

- Use Genuine Parts: Use genuine Daimler parts whenever possible to ensure compatibility and reliability.

- Document Your Repairs: Keep detailed records of all diagnostic and repair work. This can help you identify patterns and prevent future problems.

- Establish a Preventative Maintenance Program: Implement a preventative maintenance program to catch potential problems early.

11. The Benefits of Partnering with VCCarTool

Partnering with VCCarTool offers several key advantages:

11.1 Access to a Wide Range of Software Solutions

We offer a comprehensive selection of diagnostic and programming software for Daimler Trucks.

11.2 Fast and Reliable Software Downloads

Our streamlined download process ensures you get the software you need quickly and efficiently. If a download link is broken or unavailable, contact VCCarTool on WhatsApp at +1 (901) 414 – 1927 for immediate assistance.

11.3 Expert Technical Support

Our team of experienced technicians is available to provide expert support and guidance.

11.4 Competitive Pricing

We offer competitive pricing on our software solutions and services.

11.5 Improved Efficiency and Reduced Downtime

Our solutions help you diagnose and repair Daimler Trucks more efficiently, reducing downtime and saving you money.

12. Frequently Asked Questions (FAQs)

1. What diagnostic software is recommended for Daimler Trucks?

Daimler’s DiagnosticLink is a comprehensive option. Aftermarket tools like those from Snap-on and Bosch also provide good coverage.

2. How often should I update my diagnostic software?

Update your software regularly, ideally whenever new updates are released by the manufacturer.

3. What is the best way to prevent ECU programming errors?

Ensure a stable power supply, use the correct software and firmware, and follow the manufacturer’s instructions carefully.

4. Can I perform ECU programming myself, or do I need a professional?

ECU programming can be complex. Unless you have the necessary experience and equipment, it’s best to leave it to a professional.

5. What are some common causes of error codes in Daimler Trucks?

Common causes include faulty sensors, wiring problems, and malfunctioning components.

6. How can I improve my diagnostic skills?

Invest in training courses, read service manuals, and practice diagnosing problems on a variety of vehicles.

7. What is the role of telematics in Daimler Truck diagnostics?

Telematics systems provide real-time data on vehicle performance, enabling more efficient diagnostics and maintenance.

8. What is predictive maintenance, and how can it benefit my business?

Predictive maintenance uses data analysis to identify potential problems before they occur, reducing downtime and maintenance costs.

9. Are there any free diagnostic software options available for Daimler Trucks?

Some limited free options may exist, but they typically lack the comprehensive features and support of paid software.

10. How can VCCarTool help me with Daimler Truck diagnostics and programming?

*VCCarTool provides streamlined software downloads, expert technical support, and a wide range of software solutions to help you efficiently diagnose and repair Daimler Trucks.*13. Navigating Regulatory Uncertainties

Daimler Truck is closely monitoring regulatory uncertainties, including potential tariffs, which could impact future sales. The company is prepared to adjust production as needed to mitigate the effects of these uncertainties.

14. Conclusion: Empowering Your Daimler Truck Operations

Efficient diagnostics and programming are essential for maximizing the uptime and profitability of your Daimler Truck fleet. By investing in the right software, tools, and training, and partnering with a reliable provider like VCCarTool, you can streamline your operations and stay ahead in today’s competitive market. Contact VCCarTool via WhatsApp at +1 (901) 414 – 1927, email at [email protected], or visit our website at vccartool.com for expert support and solutions.

Don’t let diagnostic challenges slow you down. Contact VCCarTool today, and let us help you empower your Daimler Truck operations. Our team is ready to assist you in finding the perfect diagnostic tools and software solutions tailored to your specific needs. Take the first step towards enhanced efficiency and reduced downtime now. Reach out to us on WhatsApp at +1 (901) 414 – 1927, or send us an email at mailto:[email protected] for immediate assistance. We’re here to ensure your Daimler Trucks run smoothly and efficiently.