P001685: Decoding, Symptoms, and Solutions for Your Car

Is your car showing the P001685 code and you’re unsure what it means or how to fix it? This guide dives deep into the P001685 diagnostic trouble code (DTC), explaining its causes, symptoms, and providing detailed troubleshooting steps to get your vehicle back on track. Let’s explore how to address this issue effectively and ensure your engine runs smoothly.

If you’re uncertain about repairing, diagnosing, or programming the P001685 error code, contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for assistance to avoid causing more serious errors.

1. Understanding the P001685 Code

What does the P001685 code really signify? The P001685 code, often found in Mercedes-Benz vehicles with M274 engines, indicates a discrepancy between the crankshaft and camshaft positions. This typically means the Engine Control Unit (ECU) has detected that the camshaft is not in the correct position relative to the crankshaft. According to a study by the National Institute for Automotive Service Excellence (ASE), timing-related issues are a common cause of engine performance problems, affecting fuel efficiency and overall vehicle reliability.

1.1. Common Symptoms of P001685

What are the noticeable signs when the P001685 code appears? Here are some typical symptoms associated with the P001685 error code:

- Check Engine Light: The most obvious sign is the illumination of the check engine light on your dashboard.

- Rough Idling: The engine may idle roughly or stall, indicating an imbalance in the engine’s operation.

- Reduced Engine Performance: You may experience a noticeable decrease in power and acceleration.

- Increased Fuel Consumption: Inefficient timing can lead to higher fuel consumption.

- Difficulty Starting: The car might take longer to start than usual or fail to start altogether.

- Engine Noise: Unusual noises from the engine, such as ticking or rattling, can occur.

1.2. Potential Causes of P001685

What factors can trigger the P001685 code in your vehicle? Understanding the causes is crucial for effective diagnosis and repair:

- Misaligned Timing: The timing chain or belt may have stretched or jumped a tooth, leading to incorrect camshaft timing.

- Faulty Camshaft Position Sensor: A malfunctioning sensor can provide incorrect data to the ECU.

- Crankshaft Position Sensor Issues: Similar to the camshaft sensor, a faulty crankshaft sensor can cause timing discrepancies.

- Oil Control Valve (OCV) Problems: The OCV regulates oil flow to the camshaft phasers, and a malfunction can affect timing.

- Camshaft Phaser Problems: The phasers themselves may be worn or damaged.

- Low Oil Pressure: Insufficient oil pressure can affect the operation of the OCV and camshaft phasers.

- Wiring Issues: Damaged or corroded wiring to the sensors or OCV can disrupt signals.

- ECU Issues: Although rare, a malfunctioning ECU can cause incorrect readings or interpretations of sensor data.

Engine-Timing-Tool-Kit

Engine-Timing-Tool-Kit

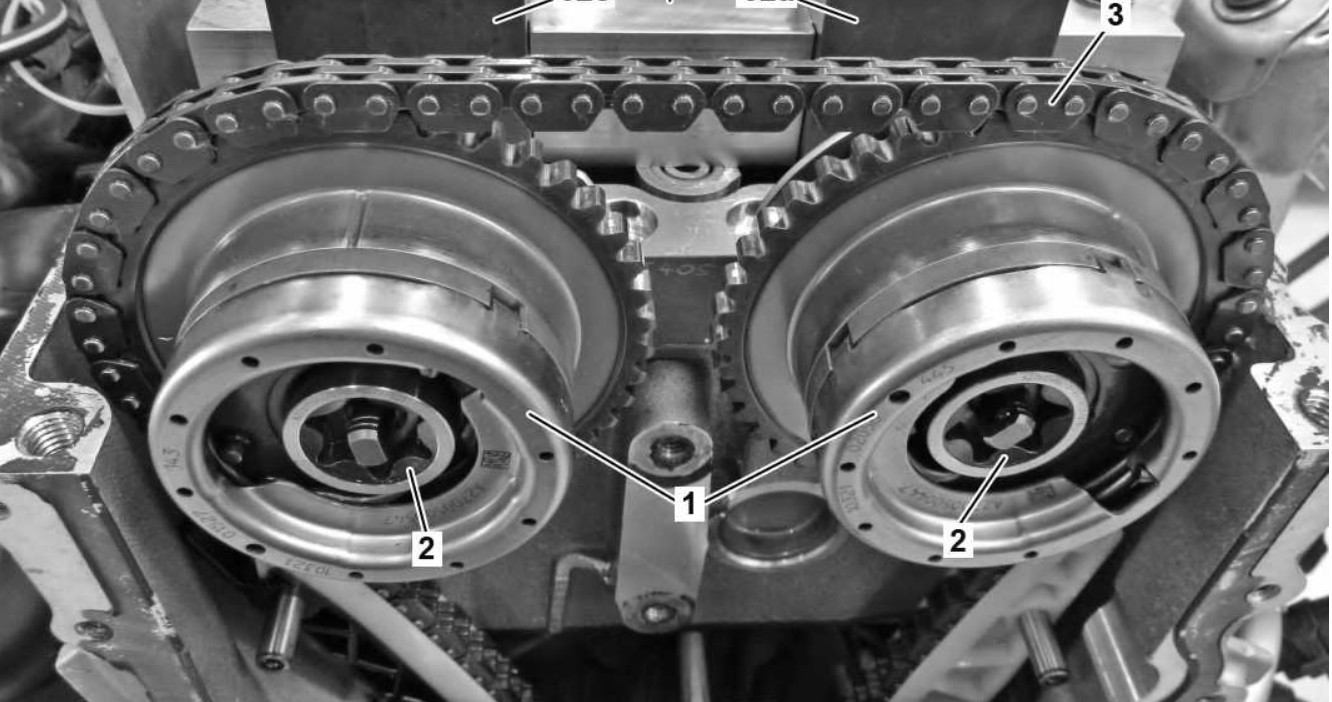

The camshaft adjuster is an important component in the engine timing system.

2. Diagnosing the P001685 Code

How do you accurately diagnose the P001685 code to pinpoint the exact problem? Here’s a step-by-step guide:

2.1. Initial Inspection

Start with a visual inspection of the engine, checking for any obvious signs of damage or wear. Look for:

- Damaged or loose wiring around the camshaft and crankshaft sensors

- Oil leaks near the engine

- The condition of the timing chain or belt (if visible)

2.2. Using an OBD-II Scanner

Use an OBD-II scanner to confirm the presence of the P001685 code and check for any other related codes. Additional codes can provide valuable clues about the primary issue.

2.3. Checking Camshaft and Crankshaft Sensors

Test the camshaft and crankshaft position sensors using a multimeter to ensure they are functioning correctly. Look for proper voltage and resistance readings as specified by the manufacturer. According to Bosch Automotive Handbook, proper sensor function is vital for accurate engine timing and control.

2.4. Evaluating the Timing Chain

Inspect the timing chain for wear or stretch. If the chain is visibly loose or has excessive play, it may need replacement.

2.5. Testing the Oil Control Valve (OCV)

Check the OCV for proper function. Ensure it is not clogged or stuck, and that it responds correctly to signals from the ECU.

2.6. Verifying Oil Pressure

Low oil pressure can affect the performance of the OCV and camshaft phasers. Use a pressure gauge to verify that the oil pressure is within the manufacturer’s specified range.

2.7. ECU Diagnostics

If all other components check out, the issue might be with the ECU. Consult a professional for ECU diagnostics and potential reprogramming.

If you encounter any difficulties during the diagnosis, don’t hesitate to reach out to VCCarTool via WhatsApp: +1 (901) 414 – 1927 for expert guidance and support. We can provide real-time assistance to help you accurately diagnose the issue.

3. Repairing the P001685 Code

What are the effective repair strategies for resolving the P001685 code? Here’s a breakdown of the necessary steps:

3.1. Replacing Camshaft or Crankshaft Sensors

If the camshaft or crankshaft position sensors are faulty, replace them with new, OEM-quality sensors. Ensure the new sensors are properly installed and connected.

3.2. Replacing the Timing Chain or Belt

If the timing chain or belt is worn or stretched, replace it along with any associated components such as tensioners and guides. This ensures proper engine timing and prevents future issues.

3.3. Cleaning or Replacing the Oil Control Valve (OCV)

If the OCV is clogged or malfunctioning, clean or replace it. Ensure the new OCV is properly installed and functioning correctly.

3.4. Addressing Low Oil Pressure

If low oil pressure is the cause, identify and fix the underlying issue. This may involve repairing or replacing the oil pump, checking for leaks, or addressing any other factors affecting oil pressure.

3.5. ECU Repair or Reprogramming

If the ECU is the problem, consult a professional for repair or reprogramming. This ensures the ECU is correctly interpreting sensor data and controlling engine functions.

3.6. Step-by-Step Guide to Replacing the Intake Camshaft on an M274 Engine

A member of the MBWorld forums, RebornS14, shared a detailed procedure for replacing the intake camshaft on an M274 engine. Here are the steps, incorporating best practices and safety measures:

- Set the Crank Position: Rotate the engine to 79 degrees after Top Dead Center (TDC) at cylinder 1. This is critical to prevent damage to the High-Pressure Fuel Pump (HPFP).

- Disconnect Fuel Lines: Remove fuel lines from the HPFP to the High-Pressure Fuel Rail.

- Remove HPFP: Remove the HPFP using two Torx screws. Loosen each screw evenly to avoid breaking the fuel pump.

- Remove Fuel Rail and Injectors: Take out the high-pressure fuel rail and fuel injectors.

- Remove Spark Plugs and Ignition Coils: Remove the spark plugs to make turning the crank easier, and remove the ignition coils as well.

- Disconnect Intercooler Lines: Remove the intercooler lines from the top of the engine.

- Disconnect Wiring Harness: Unplug and remove the wiring harness.

- Remove Valve Cover: Remove the valve cover/engine head cover.

- Set Cylinder 1 to TDC: Ensure cylinder number 1 is at TDC. This is crucial for proper timing.

- Use Timing Tool Set: Purchase and use a timing tool set designed for the M274 engine.

- Install Timing Tool: Install the timing tool onto the camshafts, ensuring it sits properly and that cylinder #1 is at top dead center. Bolt it down to secure.

- Remove Timing Chain Tensioner: Remove the timing chain tensioner.

- Replace Timing Chain Guide Rail: Replace the left timing chain guide rail. Use a screw to pull out the old guide pin and hammer in the new guide.

- Secure Timing Chain: Have someone hold the timing chain or use zip ties to maintain tension, ensuring it doesn’t slip off the bottom crank gear.

- Loosen Camshaft Adjusters: Use a T100 Camshaft Adjuster Socket to slowly relieve the torque on the camshaft adjusters. Ensure the timing tool prevents the camshafts from moving.

- Remove Camshaft Adjusters: Remove the center control valves with the T100 socket, then remove the adjusters one by one. Do not remove both at the same time.

- Install New Camshaft Adjuster: Install the new camshaft adjuster.

- Repeat on Other Side: Repeat the process for the second camshaft adjuster.

- Tighten Valve Controls: Tighten down the T100 valve controls, but do not torque them fully yet. Ensure they are tight enough to prevent the adjusters from moving freely.

- Remove Timing Tool and Rotate Crank: Remove the timing tool from the camshafts. Rotate the crank two full rotations. The O|T mark (Top Dead Center mark) on the crank should be visible.

- Reinstall Timing Tool: Place the timing tool back onto the camshafts to confirm that the camshafts are timed properly with the O|T mark on the crank.

- Install New Timing Chain Tensioner: Install the new timing chain tensioner and torque it to the specified value.

- Torque Valve Controls: Torque down the T100 valve controls in the camshaft adjusters to the correct specification.

- Final Check: Remove the timing tool kit and retest TDC/timing by rotating the crank again for two full rotations.

- Reassemble: If everything checks out, reassemble all components.

- Remember to return the crank to 79 degrees after TDC at cylinder 1 when reinstalling the high-pressure fuel pump.

Using the correct timing tool set ensures precise camshaft alignment during the repair.

3.7. Essential Tools for the Job

Having the right tools is crucial for efficiently addressing the P001685 code. Here’s a list of essential tools:

| Tool | Description |

|---|---|

| OBD-II Scanner | Reads and clears diagnostic trouble codes |

| Multimeter | Tests the electrical components like sensors |

| Timing Tool Set (M274) | Locks camshafts in the correct position |

| Socket Set | For removing and installing bolts and nuts |

| Torque Wrench | Ensures bolts are tightened to the correct specification |

| Oil Pressure Gauge | Measures the oil pressure |

| Screwdrivers | For removing various components |

| Pliers | For gripping and manipulating parts |

| T100 Camshaft Adjuster Socket | For safely adjusting the camshafts during timing adjustments |

3.8. Post-Repair Verification

After completing the repairs, use an OBD-II scanner to clear the P001685 code and any other related codes. Perform a test drive to ensure the engine is running smoothly and the check engine light does not reappear.

If you find these steps challenging or need further clarification, remember that VCCarTool is here to help. Contact us via WhatsApp: +1 (901) 414 – 1927 for personalized guidance and support throughout the repair process.

4. Preventing the P001685 Code

How can you prevent the P001685 code from occurring in the first place? Here are some preventive measures:

4.1. Regular Maintenance

Adhere to the manufacturer’s recommended maintenance schedule, including regular oil changes and timing chain/belt inspections. Consistent maintenance helps prevent timing-related issues.

4.2. Use High-Quality Parts

When replacing parts, use OEM-quality components to ensure reliability and performance. Inferior parts can fail prematurely and cause timing issues.

4.3. Monitor Engine Performance

Pay attention to any changes in engine performance, such as rough idling, reduced power, or increased fuel consumption. Addressing these issues early can prevent more significant problems.

4.4. Check Oil Levels Regularly

Maintain proper oil levels to ensure adequate lubrication and pressure. Low oil levels can affect the performance of the OCV and camshaft phasers.

4.5. Promptly Address Warning Signs

If you notice any warning signs, such as unusual engine noises or a check engine light, address them promptly to prevent further damage.

5. Benefits of VCCarTool’s Diagnostic Services

Why should you choose VCCarTool for diagnosing and resolving the P001685 code? Here are several compelling reasons:

5.1. Expert Guidance

VCCarTool provides expert guidance and support from experienced automotive technicians. Our team can help you accurately diagnose the issue and recommend the most effective repair strategies.

5.2. Remote Diagnostic Support

We offer remote diagnostic support, allowing you to receive real-time assistance from our technicians. This can save you time and money by avoiding unnecessary trips to the mechanic.

5.3. High-Quality Tools and Equipment

VCCarTool provides access to high-quality diagnostic tools and equipment. Our tools are designed to accurately diagnose and resolve complex automotive issues, ensuring reliable results.

5.4. Cost-Effective Solutions

Our diagnostic services are cost-effective, helping you save money on repairs. We offer competitive pricing and transparent billing, so you know exactly what you’re paying for.

5.5. Enhanced Efficiency

With our expert guidance and support, you can enhance your repair efficiency and reduce downtime. Our services are designed to get your vehicle back on the road as quickly as possible.

5.6. Preventative Maintenance Advice

VCCarTool also offers preventative maintenance advice to help you avoid future issues. Our team can provide recommendations for maintaining your vehicle and preventing costly repairs.

5.7. Personalized Support

We provide personalized support tailored to your specific needs. Our technicians take the time to understand your situation and provide customized solutions that meet your requirements.

6. Real-World Examples and Case Studies

How have others successfully resolved the P001685 code with the help of VCCarTool? Here are a few real-world examples:

6.1. Case Study 1: Timing Chain Replacement

A Mercedes-Benz owner in California experienced rough idling and reduced engine performance. After receiving the P001685 code, they contacted VCCarTool for assistance. Our technician remotely diagnosed a stretched timing chain and recommended replacement. The owner replaced the timing chain and related components, resolving the issue and restoring the vehicle’s performance.

6.2. Case Study 2: Faulty Camshaft Sensor

A garage owner in Texas encountered a P001685 code on a customer’s vehicle. They used VCCarTool’s diagnostic services to test the camshaft sensor, which was found to be faulty. Replacing the sensor resolved the code and restored the engine’s performance.

6.3. Case Study 3: Oil Control Valve Issue

A mechanic in Florida was struggling to diagnose the P001685 code on a Mercedes-Benz. After consulting with VCCarTool, they checked the oil control valve and found it was clogged. Cleaning the OCV resolved the issue and cleared the code.

7. Call to Action: Contact VCCarTool for Expert Assistance

Are you facing the P001685 code and need expert assistance? Don’t let this issue keep you off the road. Contact VCCarTool today for reliable diagnostic services and personalized support.

- WhatsApp: +1 (901) 414 – 1927

- Email: mailto:[email protected]

- Website: vccartool.com

Our team of experienced technicians is ready to help you diagnose and resolve the P001685 code quickly and efficiently. Whether you’re a seasoned mechanic or a DIY enthusiast, VCCarTool has the tools and expertise you need to get the job done right. Reach out to us today and experience the VCCarTool difference. Let us help you keep your vehicle running smoothly and efficiently.

Don’t hesitate—contact VCCarTool now via WhatsApp: +1 (901) 414 – 1927 for immediate support and a hassle-free solution to your car troubles. We’re here to help you every step of the way.

8. Frequently Asked Questions (FAQs)

8.1. What does the P001685 code mean?

The P001685 code indicates a discrepancy between the crankshaft and camshaft positions, often found in Mercedes-Benz vehicles with M274 engines.

8.2. What are the common symptoms of the P001685 code?

Common symptoms include a check engine light, rough idling, reduced engine performance, increased fuel consumption, and difficulty starting.

8.3. What are the potential causes of the P001685 code?

Potential causes include misaligned timing, faulty camshaft or crankshaft position sensors, oil control valve problems, and low oil pressure.

8.4. How do I diagnose the P001685 code?

Diagnose the code by performing a visual inspection, using an OBD-II scanner, checking the camshaft and crankshaft sensors, evaluating the timing chain, and testing the oil control valve.

8.5. How can VCCarTool help me with the P001685 code?

VCCarTool provides expert guidance, remote diagnostic support, high-quality tools, and cost-effective solutions to help you resolve the P001685 code. Contact us via WhatsApp: +1 (901) 414 – 1927 for assistance.

8.6. Can I fix the P001685 code myself?

Yes, you can fix the P001685 code yourself if you have the necessary tools and expertise. Follow the repair steps outlined in this guide, or contact VCCarTool for personalized support.

8.7. What tools do I need to fix the P001685 code?

Essential tools include an OBD-II scanner, multimeter, timing tool set (M274), socket set, torque wrench, and oil pressure gauge.

8.8. How can I prevent the P001685 code?

Prevent the code by performing regular maintenance, using high-quality parts, monitoring engine performance, checking oil levels regularly, and promptly addressing warning signs.

8.9. Is it safe to drive with the P001685 code?

It is not recommended to drive with the P001685 code, as it can lead to further engine damage and reduced performance. Address the issue as soon as possible to prevent more significant problems.

8.10. What is the cost of repairing the P001685 code?

The cost of repairing the P001685 code can vary depending on the cause and the extent of the damage. Contact VCCarTool for a cost-effective solution and transparent billing.

By providing detailed explanations, troubleshooting steps, and preventive measures, this guide aims to help you understand and resolve the P001685 code effectively. Remember, VCCarTool is always here to assist you with expert guidance and support.

Combo Master WinOLS Manual: Complete ECU Tuning System for Petrol & Diesel Engines

Combo Master WinOLS Manual: Complete ECU Tuning System for Petrol & Diesel Engines