Coding new VGS | How to VGS programming assistance

We understand the critical role the Vehicle Gear Selector (VGS) plays in modern vehicles and how crucial it is to get replacements and coding right. This guide will illuminate the process of coding a new VGS, ensuring smooth operation and getting your customers back on the road swiftly. Discover how VCCarTool can equip you with the necessary tools and knowledge to master this essential procedure. (Video tutorial below)

1. Grasping the Essentials of Coding New VGS

The Vehicle Gear Selector, or VGS, is a vital electronic control unit within an automatic transmission system. It’s responsible for interpreting the driver’s gear selection and relaying this information to the transmission control module. When a VGS unit fails or is replaced, it needs to be precisely configured, a process known as coding, to communicate effectively with the vehicle’s other electronic systems. This programming ensures the new VGS functions seamlessly with the specific make, model, and transmission of the vehicle. Proper coding of the new VGS unit is paramount for optimal transmission performance, safety, and overall vehicle operation.

2. Essential Requirements for Programming a New VGS

Successfully coding a new VGS unit demands the right tools and knowledge. Here’s a breakdown of the key requirements:

2.1 Diagnostic Software

Specialized diagnostic software is indispensable for communicating with the vehicle’s electronic control units and performing the coding procedure. Two prominent software options include:

- Vediamo Mercedes: This comprehensive software is widely used for in-depth diagnostics, programming, and engineering functions on Mercedes-Benz vehicles. It offers extensive control over vehicle systems, including transmission control units and VGS modules.

- Mercedes DTS Monaco: Another powerful diagnostic tool, DTS Monaco, provides similar capabilities to Vediamo, focusing on diagnostics, testing, and programming of electronic control units in various vehicle brands, including Mercedes-Benz. Its user-friendly interface and guided procedures make complex tasks more manageable.

Both software solutions allow technicians to establish a connection with the vehicle’s onboard computer, access the transmission control module, and initiate the coding sequence for the new VGS.

2.2 Compatible Diagnostic Interface

A reliable diagnostic interface is crucial for the physical connection between your computer running the diagnostic software and the vehicle’s diagnostic port (typically an OBD-II port). For Mercedes-Benz vehicles, a C4 multiplexer is the mandatory interface. This device acts as a translator, enabling seamless communication between the software and the vehicle’s electronic systems. Ensure your interface is genuine and properly configured for reliable data transfer during the coding process.

2.3 New or Prepared VGS Unit

The VGS unit itself is the component being programmed. Understanding the condition of the new unit is important:

- Factory New VGS: A brand-new VGS unit directly from the manufacturer will require initial programming or “virginizing” before it can be coded to a specific vehicle. This step prepares the unit for its unique vehicle identification number (VIN) and configuration data.

- Used VGS (Renewed or Virginized): A previously used VGS unit can be recoded if it has been properly renewed or “virginized.” This process essentially resets the unit, removing its previous vehicle-specific data, allowing it to be programmed to a new vehicle. Ensure the used unit you intend to code has undergone this renewal or virginization procedure.

Why Choose VCCarTool for Your VGS Coding Needs?

At VCCarTool, we understand the demands of modern auto repair. We offer a comprehensive range of high-quality diagnostic tools and software solutions, including Vediamo, DTS Monaco, and genuine C4 multiplexers, to empower you in efficiently coding new VGS units. Our products are sourced from reputable manufacturers, ensuring reliability and accurate performance. We also provide expert support to guide you through the process, ensuring you have the confidence and knowledge to tackle any VGS coding job. Investing in tools from VCCarTool means investing in efficiency, accuracy, and customer satisfaction for your garage.

3. Step-by-Step Guide: How to Code a New VGS System

Coding a new VGS unit involves a meticulous process. While the exact steps may vary slightly depending on the diagnostic software and vehicle model, here’s a general overview:

- Preparation:

- Ensure the vehicle’s battery is fully charged or connected to a stable power supply.

- Connect the C4 multiplexer to the vehicle’s OBD-II port and your computer via a reliable connection (USB or Wi-Fi).

- Launch your chosen diagnostic software (Vediamo or DTS Monaco).

- Vehicle Identification:

- Within the software, establish communication with the vehicle. This usually involves manually selecting the vehicle model or allowing the software to automatically identify it.

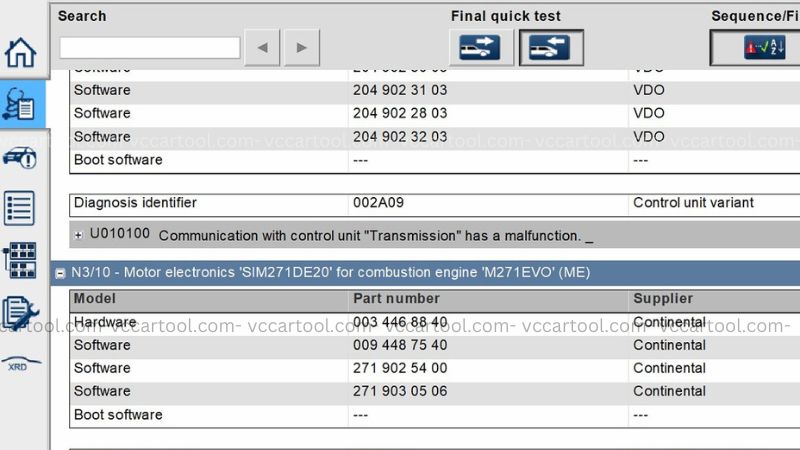

- Accessing the Transmission Control Unit:

- Navigate through the software’s menus to locate and select the transmission control unit (TCU) or the VGS module.

- Reading Existing Data (If Applicable):

- If replacing a faulty VGS, it’s often beneficial to read and save the existing configuration data from the old unit (if communication is still possible). This data can sometimes be transferred to the new unit, streamlining the coding process.

- Identifying the New VGS Unit:

- The software will typically prompt you to identify the new VGS unit. This might involve entering part numbers or allowing the software to automatically detect the new module.

- Virginizing or Initializing (If Necessary):

- For a brand-new VGS unit, you’ll likely need to perform a “virginizing” or initialization procedure. This step prepares the unit for its specific vehicle. Follow the software’s guided instructions for this process.

- Coding the New VGS:

- This is the core of the procedure. The software will guide you through the steps to program the new VGS with the vehicle’s specific configuration parameters, including the VIN and transmission adaptation data. This process may involve automatic coding routines or manual configuration options.

- Performing SCN Coding (Software Calibration Number):

- For many modern Mercedes-Benz vehicles, SCN coding is a critical step. This online process communicates with the manufacturer’s servers to download and apply the correct software calibration data for the specific vehicle and VGS unit. This ensures the VGS software is up-to-date and correctly matched to the vehicle. An active internet connection is required for SCN coding.

- Adaptations and Teach-in Procedures:

- After coding, the transmission may require adaptation or teach-in procedures. These steps allow the transmission control unit and the new VGS to learn and adjust to each other, ensuring smooth gear changes. The software will typically guide you through these procedures, which might involve driving the vehicle through specific gear ranges.

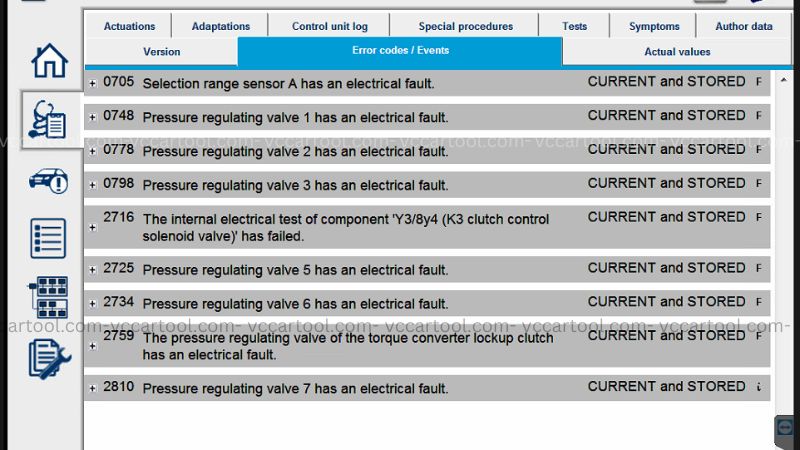

- Verification and Testing:

- Once the coding and adaptation are complete, it’s crucial to verify the correct operation of the transmission. This includes checking for any diagnostic trouble codes (DTCs) and performing a thorough test drive to ensure smooth and proper gear shifting in all driving conditions.

Expert Tip from VCCarTool: Always follow the specific instructions provided by your diagnostic software and the vehicle manufacturer’s service manual. Incorrect coding can lead to transmission problems and other vehicle malfunctions.

Video tutorial Coding New VGS below:

4. Exploring VGS Coding Languages

The actual coding of the VGS unit isn’t typically done in high-level programming languages like Python or Java in the field. Instead, it involves the transfer and configuration of specific data sets and parameters within the diagnostic software environment. These software platforms utilize proprietary protocols and data formats to communicate with the vehicle’s electronic control units.

However, the development of the VGS software itself by the manufacturers and their suppliers involves various programming languages and engineering principles. Embedded C and C++ are commonly used for developing the firmware that runs directly on the VGS microcontrollers. These languages offer the necessary performance and control over hardware resources required for real-time automotive applications. Additionally, assembly language might be used for highly optimized low-level operations.

Therefore, while technicians performing VGS coding won’t be writing lines of C++ code, understanding that sophisticated software engineering underpins the diagnostic tools they use provides valuable context.

5. Best Practices for Efficient VGS Coding

To ensure successful and efficient VGS coding, consider these best practices:

- Use Reliable Equipment: Invest in genuine and high-quality diagnostic software and interfaces like those offered by VCCarTool. Reliable tools minimize the risk of errors and communication issues.

- Ensure Stable Power: Maintain a stable power supply to the vehicle throughout the coding process to prevent interruptions that could damage electronic control units.

- Follow Instructions Meticulously: Carefully read and follow the step-by-step instructions provided by your diagnostic software and the vehicle manufacturer.

- Back Up Data When Possible: Before starting the coding process, back up any existing configuration data from the old VGS unit if communication allows.

- Verify Software Compatibility: Ensure your diagnostic software is up-to-date and compatible with the specific vehicle model and VGS unit you are working on.

- Perform Thorough Testing: After coding, always perform a comprehensive test drive to verify proper transmission operation in all driving modes.

- Document Your Work: Keep a record of the coding process, including any specific configurations or adaptations performed. This documentation can be helpful for future reference or troubleshooting.

VCCarTool: Your Partner in Automotive Excellence

At VCCarTool, we are committed to providing automotive technicians and garage owners with the tools and support they need to excel. Our selection of diagnostic equipment is designed to meet the demands of modern vehicle technology, including the intricacies of VGS coding. By choosing VCCarTool, you gain access to:

- High-Quality Products: Reliable and genuine diagnostic tools and software.

- Expert Support: Our knowledgeable team is ready to assist you with product selection and technical guidance.

- Competitive Prices: We offer excellent value for your investment.

- Up-to-Date Solutions: We stay current with the latest advancements in automotive diagnostics.

6. Coding New VGS at VCCarTool: Empowering Your Success

While VCCarTool is a supplier of diagnostic tools and software, we empower your ability to perform coding new VGS effectively. Our range of products, including Vediamo, DTS Monaco, and the essential C4 multiplexer, provides you with the necessary hardware and software foundation for this critical task.

Imagine this scenario: A customer brings in a Mercedes-Benz with transmission issues. Your diagnosis points to a faulty VGS unit. With the tools purchased from VCCarTool, you can confidently:

- Connect your genuine C4 multiplexer to the vehicle.

- Launch your licensed Vediamo or DTS Monaco software.

- Identify the new VGS unit.

- Perform the necessary initialization or virginization.

- Code the new VGS module with precision.

- Execute SCN coding to ensure optimal software calibration.

- Perform any required adaptations.

- Thoroughly test the transmission to guarantee smooth operation.

By utilizing the resources available through VCCarTool, you can enhance your garage’s capabilities, reduce repair times, and increase customer satisfaction. You can confidently tackle complex VGS replacements and coding procedures, positioning your business as a leader in automotive service.

Ready to elevate your auto repair capabilities? Contact VCCarTool today to explore our range of diagnostic tools and software.

- WhatsApp: +1 (901) 414 – 1927

- Website: vccartool.com

Our friendly and knowledgeable team is ready to answer your questions and help you find the perfect tools to meet your specific needs. Don’t let VGS coding challenges slow you down. Partner with VCCarTool and experience the difference that quality equipment and expert support can make. Equip your garage for success and ensure you can handle any modern vehicle repair with confidence and efficiency. Reach out now and let us help you take your business to the next level. Investing in the right tools is an investment in your future and the satisfaction of your customers.