P0365 Camshaft Position Sensor B Circuit Bank 1: How to Fix

Is your car throwing a P0365 code? This article dives deep into the P0365 camshaft position sensor B circuit bank 1 code, offering clear guidance on diagnosis and repair, with insights from the experts at VCCarTool. We aim to provide you with the knowledge to tackle this issue effectively, ensuring your vehicle runs smoothly.

If you are unsure how to diagnose or repair the P0365 camshaft position sensor B circuit bank 1 code, contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for assistance to avoid causing further damage.

1. Understanding the P0365 Code: Camshaft Position Sensor B Circuit Bank 1

The P0365 code indicates a problem within the circuit of the camshaft position sensor “B” for bank 1. This means the engine control module (ECM) isn’t receiving the expected signal from this sensor, potentially affecting engine timing and performance.

1.1. What Does the Camshaft Position Sensor Do?

The camshaft position sensor plays a vital role in your vehicle’s engine management system. It monitors the position of the camshaft, relaying this information to the ECM. This data is crucial for:

- Fuel Injection Timing: Optimizing when fuel is injected into the cylinders.

- Ignition Timing: Ensuring the spark plugs fire at the correct moment.

- Engine Synchronization: Coordinating the camshaft and crankshaft positions for smooth operation.

1.2. Bank 1 and Sensor B: Decoding the Terminology

- Bank 1: Refers to the side of the engine containing cylinder number 1. In an inline engine, there’s only one bank. On a V-shaped engine, there are two.

- Sensor B: Typically indicates the exhaust camshaft position sensor. Sensor “A” is usually the intake camshaft sensor.

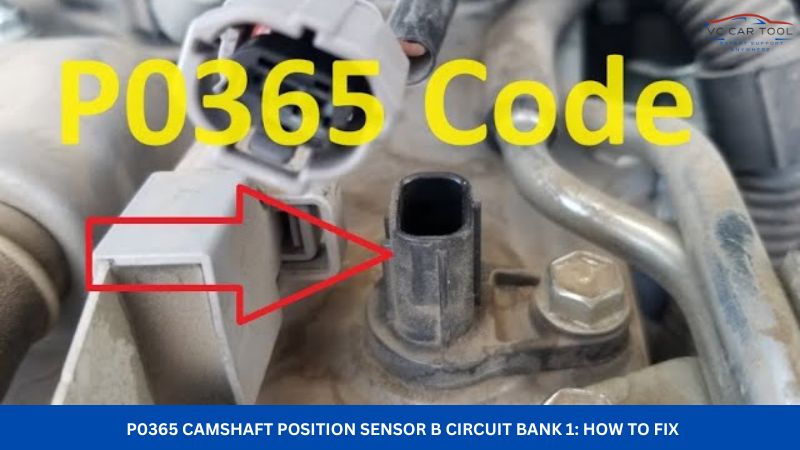

Camshaft position sensor location on an engine, highlighting its proximity to the camshaft and crankshaft.

2. Symptoms of a P0365 Code

When the P0365 code appears, you might observe the following symptoms:

- Check Engine Light: The most common indicator.

- Rough Running Engine: Misfires or erratic idling.

- Reduced Engine Power: Noticeable decrease in acceleration.

- Difficulty Starting: The engine may crank longer than usual before starting.

- Stalling: The engine might stall unexpectedly.

- Poor Fuel Economy: A drop in miles per gallon.

These symptoms highlight the importance of addressing the P0365 code promptly to prevent potential drivability issues and further engine damage. VCCarTool can provide expert guidance to quickly diagnose and resolve these issues. Contact us via WhatsApp: +1 (901) 414 – 1927 for immediate assistance.

3. Potential Causes of the P0365 Code

Several factors can trigger the P0365 code, including:

- Faulty Camshaft Position Sensor: The sensor itself may be defective.

- Wiring Issues: Damaged, corroded, or loose wiring to the sensor.

- Connector Problems: Corroded or loose connector at the sensor.

- Timing Chain Issues: A stretched or worn timing chain can affect camshaft timing.

- ECM Malfunction: In rare cases, the ECM itself may be faulty.

Addressing the root cause is crucial for a lasting repair. Let VCCarTool help you pinpoint the exact problem. Reach out via WhatsApp: +1 (901) 414 – 1927 for expert diagnostic support.

4. Diagnosing the P0365 Code: A Step-by-Step Guide

Diagnosing the P0365 code requires a systematic approach:

4.1. Gather Information

- Record the Code: Use an OBD-II scanner to confirm the P0365 code and any other related codes.

- Research Technical Service Bulletins (TSBs): Check for TSBs related to the P0365 code for your specific vehicle make and model.

4.2. Visual Inspection

- Inspect Wiring and Connectors: Look for any signs of damage, corrosion, or looseness in the wiring and connectors leading to the camshaft position sensor.

- Check the Sensor: Visually inspect the sensor for any physical damage.

4.3. Sensor Testing

- Resistance Test: Use a multimeter to check the sensor’s resistance. Refer to the vehicle’s service manual for the correct resistance values.

- Signal Test: With the engine running, use a multimeter or oscilloscope to check the sensor’s signal output. Again, consult the service manual for specifications.

4.4. Wiring Circuit Testing

- Continuity Test: Use a multimeter to check the continuity of the wiring between the sensor and the ECM.

- Voltage Test: Check for proper voltage at the sensor connector.

4.5. Timing Chain Inspection

- Check Timing Marks: Verify that the timing marks on the crankshaft and camshaft align correctly.

- Listen for Timing Chain Noise: Excessive rattling or noise from the timing chain area could indicate a problem.

Note: According to a study by the National Institute for Automotive Service Excellence (ASE), proper diagnosis is critical for effective auto repair. ASE-certified technicians demonstrate expertise in diagnosing and repairing vehicle issues, ensuring accurate and reliable service.

Navigating these diagnostic steps can be complex. VCCarTool offers remote diagnostic services to guide you through each stage. Contact us via WhatsApp: +1 (901) 414 – 1927 for expert assistance.

5. Repairing the P0365 Code: Solutions and Procedures

Once you’ve identified the cause of the P0365 code, here are potential repair solutions:

5.1. Replacing the Camshaft Position Sensor

- Disconnect the electrical connector.

- Remove the bolt holding the sensor in place.

- Install the new sensor and tighten the bolt to the specified torque.

- Reconnect the electrical connector.

5.2. Repairing Wiring and Connectors

- Repair Damaged Wiring: Replace any damaged sections of wiring with new wire of the same gauge.

- Clean Corroded Connectors: Use a wire brush or electrical contact cleaner to remove corrosion from connectors.

- Secure Loose Connectors: Ensure connectors are fully seated and locked in place.

5.3. Addressing Timing Chain Issues

- Replace Timing Chain: If the timing chain is stretched or worn, replace it along with any associated components like tensioners and guides.

- Verify Timing Alignment: After replacing the timing chain, ensure the timing marks are properly aligned.

5.4. ECM Repair or Replacement

- Consult a Specialist: If the ECM is suspected, consult a qualified specialist for testing and repair.

- Replace ECM: If the ECM is faulty, it may need to be replaced and reprogrammed.

Performing these repairs requires precision and expertise. VCCarTool provides detailed repair guidance and support. Contact us via WhatsApp: +1 (901) 414 – 1927 for expert advice.

6. Cost of Repairing the P0365 Code

The cost of repairing the P0365 code can vary depending on the cause and the vehicle:

| Repair | Estimated Cost (USD) |

|---|---|

| Camshaft Position Sensor Replacement | $100 – $300 |

| Wiring/Connector Repair | $50 – $200 |

| Timing Chain Replacement | $800 – $2000 |

| ECM Repair/Replacement | $500 – $1500 |

| Diagnostic Fee | $75 – $150 |

These costs are estimates and can vary based on location, labor rates, and the specific vehicle model.

Worried about repair costs? VCCarTool offers cost-effective diagnostic and repair solutions. Contact us via WhatsApp: +1 (901) 414 – 1927 for affordable options.

7. Preventing the P0365 Code

While some issues are unavoidable, you can take steps to minimize the risk of encountering the P0365 code:

- Regular Maintenance: Follow your vehicle’s recommended maintenance schedule, including oil changes and timing belt/chain replacements.

- Inspect Wiring Regularly: Periodically inspect wiring and connectors for damage or corrosion.

- Address Issues Promptly: Don’t ignore warning signs like a check engine light or rough running engine.

Proactive maintenance is key to preventing costly repairs. VCCarTool can help you create a maintenance plan tailored to your vehicle. Contact us via WhatsApp: +1 (901) 414 – 1927 for personalized advice.

8. Advanced Diagnostic Tools and Techniques

For more complex cases, advanced diagnostic tools and techniques may be necessary:

- Oscilloscope Diagnostics: Using an oscilloscope to analyze the camshaft position sensor signal can reveal subtle issues that a multimeter might miss.

- Factory Scan Tools: Factory scan tools provide access to more detailed diagnostic information and programming capabilities.

- Data Logging: Recording engine data while driving can help identify intermittent problems that are difficult to diagnose in the shop.

Access to advanced tools and expertise is essential for tackling challenging diagnostic scenarios. VCCarTool provides access to cutting-edge diagnostic equipment and expert technicians. Contact us via WhatsApp: +1 (901) 414 – 1927 to elevate your diagnostic capabilities.

9. Why Choose VCCarTool for P0365 Code Solutions?

- Expert Technicians: Our team of experienced technicians possesses in-depth knowledge of automotive diagnostics and repair.

- Remote Diagnostic Support: We offer remote diagnostic services to guide you through the troubleshooting process.

- Cost-Effective Solutions: We provide affordable repair options without compromising quality.

- Cutting-Edge Equipment: We utilize state-of-the-art diagnostic tools to ensure accurate and efficient repairs.

Don’t let the P0365 code slow you down. Choose VCCarTool for reliable solutions and expert support. Contact us today via WhatsApp: +1 (901) 414 – 1927 or email at [email protected] to experience the difference. Visit our website at vccartool.com for more information.

10. Call to Action: Get Immediate Assistance from VCCarTool

Struggling with the P0365 code? Don’t waste time and money on guesswork. Let VCCarTool provide the expert guidance you need. Whether you’re a seasoned mechanic or a DIY enthusiast, our remote diagnostic services and experienced technicians can help you pinpoint the problem and find the right solution.

Contact VCCarTool now via WhatsApp: +1 (901) 414 – 1927 for immediate assistance. We’re available to answer your questions, provide diagnostic support, and offer cost-effective repair options.

Stop struggling and start solving. Contact VCCarTool today!

FAQ: P0365 Code

1. What does the P0365 code mean?

The P0365 code indicates a problem within the circuit of the camshaft position sensor “B” for bank 1.

2. Can I drive with a P0365 code?

It’s not recommended. Driving with a P0365 code can lead to reduced engine performance, stalling, and potential engine damage.

3. How do I fix a P0365 code?

Fixing a P0365 code involves diagnosing the root cause, which could be a faulty sensor, wiring issues, or timing chain problems. Repairing or replacing the affected components will resolve the issue. Contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for assistance.

4. How do I test a camshaft position sensor?

You can test a camshaft position sensor using a multimeter to check its resistance and signal output. Refer to your vehicle’s service manual for the correct testing procedures and values.

5. What is bank 1 on an engine?

Bank 1 is the side of the engine that contains cylinder number 1. On an inline engine, there’s only one bank. On a V-shaped engine, there are two.

6. What is sensor B on an engine?

Sensor B typically refers to the exhaust camshaft position sensor.

7. How much does it cost to replace a camshaft position sensor?

The cost to replace a camshaft position sensor typically ranges from $100 to $300, including parts and labor.

8. Can a bad camshaft position sensor cause a no-start condition?

Yes, a faulty camshaft position sensor can cause a no-start condition because the ECM needs its signal to properly time fuel injection and ignition.

9. What are the symptoms of a bad camshaft position sensor?

Symptoms of a bad camshaft position sensor include a check engine light, rough running engine, reduced engine power, difficulty starting, and stalling.

10. Is it easy to replace a camshaft position sensor?

Replacing a camshaft position sensor is generally a straightforward repair, but it’s essential to follow the correct procedures and torque specifications. If you are unsure, contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for assistance to avoid causing further damage.