ICOM NEXT Review: The Ultimate Guide for BMW Diagnostics & Programming

Are you a BMW technician or garage owner seeking a reliable diagnostic and programming tool? This ICOM NEXT review will provide you with an in-depth analysis of this powerful tool, comparing it with alternatives and highlighting its key features. Whether you’re diagnosing complex issues or programming new modules, the right tool can significantly boost your efficiency and accuracy. Discover how the ICOM NEXT can enhance your capabilities in automotive diagnostics, coding, and module programming.

1. Understanding the ICOM NEXT: What is it?

The ICOM NEXT is a diagnostic and programming interface designed for BMW vehicles. It serves as a communication bridge between the vehicle’s electronic control units (ECUs) and diagnostic software like ISTA-D and ISTA-P. This tool enables technicians to perform advanced functions such as reading fault codes, programming modules, and performing complex diagnostics. In essence, the ICOM NEXT provides a comprehensive solution for maintaining and repairing BMW vehicles, enhancing your ability to offer top-tier services with efficient troubleshooting and module updates.

2. Why Choose ICOM NEXT for BMW Diagnostics?

Why is the ICOM NEXT a preferred choice for BMW diagnostics and programming? Here are some compelling reasons:

- Comprehensive Diagnostics: The ICOM NEXT facilitates in-depth diagnostics, allowing technicians to identify and resolve issues accurately.

- Module Programming: It supports module programming, enabling the updating or replacement of ECU software.

- Compatibility: The ICOM NEXT is compatible with a wide range of BMW models, making it a versatile tool for various BMW vehicles.

- Efficiency: The tool’s performance can reduce diagnostic and programming times, improving overall efficiency.

- Wireless Connectivity: Wireless connectivity offers increased flexibility and ease of use in the workshop.

3. Key Features and Benefits of ICOM NEXT

The ICOM NEXT offers several features that set it apart as a high-performance diagnostic tool:

- Faster Processing: Improved hardware allows for faster data processing and reduced programming times.

- Enhanced Durability: The robust design ensures reliability and longevity, even in demanding workshop conditions.

- Wireless Connectivity: The ICOM NEXT comes equipped with reliable wireless connectivity, allowing technicians to move freely around the vehicle while performing diagnostics.

- Backward Compatibility: It supports older BMW models, ensuring a broad range of vehicle coverage.

- Self-Testing Capabilities: The built-in self-testing features help identify any hardware issues, ensuring optimal performance.

4. ICOM NEXT Clone Options: SP269-B1 vs. SP269-D

When considering ICOM NEXT, you’ll encounter clone options. Here’s a comparison of two popular models: SP269-B1 and SP269-D.

| Feature | SP269-B1 | SP269-D |

|---|---|---|

| Quality | Clone from original ICOM Next, best chip, fiber programming, faster speed, supports older vehicles pre-2000, and can handle motorcycles. | ICOM Next using VXDIAG Solution, based on VX Manager driver. |

| Price | Higher Price | Lower Price |

| Chip Quality | Premium Chips | Standard Chips |

| Software Support | Compatible with ISTA-D, ISTA-P, E-SYS, INPA, WinKFP, Tool32, NCS Expert | Compatible with ISTA-D, ISTA-P, E-SYS, INPA, WinKFP, Tool32, NCS Expert |

| Connectivity | Wi-Fi, LAN | Wi-Fi, LAN |

| Special Features | Fiber programming, supports older vehicles pre-2000, motorcycle support | VX Manager detects device connection status, emulates ICOM with additional software |

| Firmware Update | Yes | Yes |

| Target User | Professional technicians needing comprehensive support, including older vehicles and motorcycles. Those who want to future-proof their investment with a device capable of handling a wide range of tasks. | Garages or technicians seeking a cost-effective solution, focusing on newer BMW models. Those who are comfortable with additional software configuration for full emulation capabilities. |

Consider SP269-B1 for superior quality and broader compatibility, especially if you work on older models or motorcycles. Opt for SP269-D if you’re seeking a budget-friendly option with reliable performance for newer BMW vehicles.

5. Real User Experiences: ICOM NEXT Reviews

Here are insights from real users who’ve utilized the ICOM NEXT in their workshops:

- Enhanced Speed and Build Quality: “ICOM Next is faster than the old BMW ICOM. It is also better built and offers WIFI connectivity. It handles multi-programming and coding efficiently.”

- Reliable Performance: “I have an ICOM Next clone that works perfectly without any issues.”

- Value for Money: “My Chinese NEXT has been working for over a year without problems. You get what you pay for in terms of quality and reliability.”

- Quality Components: “The quality is very good, the ENET cable is long, and the OBD cable is durable. I like it so much.”

- Effective Heat Dissipation: “My old ICOM A2 burned out due to long hours of connection. This ICOM Next seems to work well with heat dissipation.”

- Stable Wireless Connection: “The WiFi connection is strong and stable, and the LAN cable works fine. It’s easy to program the EGS transmission control module of BMW.”

These reviews emphasize the ICOM NEXT’s speed, reliability, and build quality, making it a valuable asset for automotive technicians.

6. ICOM NEXT vs. Alternatives: VXDIAG VCX SE BMW & Super ICOM Pro N3+

With several diagnostic tools available, understanding the differences between the ICOM NEXT and its alternatives is essential. Here’s a comparison with VXDIAG VCX SE BMW and Super ICOM Pro N3+:

6.1. VXDIAG VCX SE BMW vs. ICOM NEXT Clone

| Feature | VXDIAG VCX SE BMW | ICOM NEXT Clone |

|---|---|---|

| Cost | Lower | Higher |

| Size | Smaller | Larger |

| Adapter Needs | Doesn’t need different adapters for E and F/G series | Needs different adapters for E and F/G series |

| ISTA+ Compatibility | Compatible with the original ISTA+ (latest version) | May not be compatible with the original ISTA+ |

| Motorcycle Support | No | Yes |

| Device Connection Status | VX Manager detects device connection status | No built-in detection |

| Remote Diagnosis | Enabled with DoNet remote diagnosis | Not available |

| Series Compatibility | Works with all series E, F, G, and I | Works with all series E, F, G, and I |

| Functionality | Full vehicle diagnostics, error erasing, factory option encoding, module programming | Full vehicle diagnostics, error erasing, factory option encoding, module programming |

| Software Compatibility | Rheingold, ISTA +, ISTA D, ISTA P, E-SYS programs, INPA, WinKFP, Tool32, NCS Expert | Rheingold, ISTA +, ISTA D, ISTA P, E-SYS programs, INPA, WinKFP, Tool32, NCS Expert |

| Firmware Update | Yes | Yes |

| Target User | Technicians or small car services looking for a cost-effective solution with essential functionality. | Professional workshops requiring comprehensive diagnostics and programming, especially for older models and motorcycles. |

| Considerations | Ideal for users who prioritize cost savings and don’t require motorcycle support. | Best for users who need a robust tool with broader compatibility and advanced features. |

| Remote Support Needs | Users who need remote support options for diagnostics and programming, leveraging DoNet for efficient assistance. | Users who do not require remote support capabilities and prefer a traditional, comprehensive diagnostic solution. |

6.2. Super ICOM Pro N3+ vs. ICOM NEXT

| Feature | Super ICOM Pro N3+ | ICOM NEXT |

|---|---|---|

| Housing Design | Different housing compared to ICOM series; adapts original ICOM solution | Standard ICOM housing |

| Firmware Upgrade | Users can download firmware from the original ICOM server | Firmware updates available |

| Software Compatibility | Fully compatible with ICOM software ISTA-D, ISTA-P, E-sys, INPA, WinKFP, etc. | Compatible with ICOM software ISTA-D, ISTA-P, E-sys, INPA, WinKFP, etc. |

| Functionality | Can be used as DoIP and J2534 passthrough device via a one-key switch button | Standard diagnostic and programming functions |

| Target User | Professional technicians looking for a versatile tool that can function as both a diagnostic interface and a passthrough device. | Professional technicians needing a reliable diagnostic and programming interface |

| Considerations | Best for users who need the flexibility of switching between diagnostic and passthrough modes for various vehicle protocols. | Ideal for users who primarily need comprehensive diagnostics and programming without the additional need for passthrough functionality. |

| Versatility in Protocols | Users who work with a range of vehicle protocols and require a tool that can adapt to different communication standards effortlessly. | Technicians primarily focused on BMW vehicles, where standard diagnostic and programming functions are sufficient without needing to switch to other vehicle protocols. |

| Future-Proofing | Offers adaptability to future vehicle technologies, supporting DoIP and J2534 standards for long-term usability. | Remains effective for current BMW models but may require additional tools for vehicles utilizing newer communication protocols. |

| Hardware Longevity | Designed with robust components and firmware upgrade capabilities, ensuring extended operational life. | Well-built but may be superseded by newer models with advanced features over time. |

| Integration Needs | Simplifies integration into existing diagnostic setups by combining multiple functionalities into a single device. | Requires additional devices for specific tasks like DoIP and J2534 passthrough, which may complicate workflow in certain situations. |

Choosing the right tool depends on your specific needs and budget. The VXDIAG VCX SE BMW offers a cost-effective alternative with essential functionalities, while the Super ICOM Pro N3+ provides added versatility as a passthrough device.

7. ICOM NEXT Firmware Updates: Keeping Your Tool Up-to-Date

Regular firmware updates are crucial for maintaining optimal performance and compatibility. Here’s a brief guide:

- Check for Updates: Use the VX Manager software to check for available firmware updates.

- Download Firmware: Download the latest firmware version.

- Install Updates: Follow the on-screen instructions to install the firmware.

- Verify Installation: Confirm the successful installation by checking the firmware version in the VX Manager.

Keeping your ICOM NEXT updated ensures access to the latest features and improvements.

8. Troubleshooting Common ICOM NEXT Issues

Even with a top-tier tool like the ICOM NEXT, you might encounter occasional issues. Here are some common problems and how to address them:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Connection Problems | Faulty cable, incorrect settings | Check cable connections, verify Ethernet or Wi-Fi settings, ensure the correct IP address is configured. |

| Software Installation Errors | Incompatible software versions, corrupted files | Reinstall the software, ensure compatibility with your operating system, download software from trusted sources. |

| Firmware Update Failures | Interrupted update process, power loss | Ensure a stable power supply, avoid interruptions during the update, retry the update process, contact support if the issue persists. |

| Slow Performance | Outdated firmware, hardware limitations | Update firmware, optimize computer performance, consider upgrading hardware if necessary. |

| Device Not Recognized | Driver issues, hardware malfunction | Reinstall drivers, check device manager for errors, test the device on another computer, contact technical support for hardware diagnostics. |

| Inability to Program Modules | Incorrect programming data, communication errors | Verify programming data, check vehicle battery voltage, ensure stable connection during programming, consult vehicle-specific documentation. |

| Wi-Fi Connectivity Problems | Weak signal, incorrect network settings | Improve Wi-Fi signal strength, verify network settings, ensure the correct SSID and password are used, check for interference. |

| License Activation Issues | Incorrect license key, activation server problems | Verify the license key, ensure an active internet connection, contact the software vendor for assistance. |

For further assistance, don’t hesitate to reach out to VCCarTool via WhatsApp: +1 (901) 414 – 1927 for expert guidance and support.

9. Optimizing Your ICOM NEXT Setup

To maximize the efficiency of your ICOM NEXT, consider these optimization tips:

- Stable Power Supply: Use a stable power supply to prevent interruptions during programming.

- Wired Connection: When possible, use a wired Ethernet connection for faster and more reliable data transfer.

- Software Updates: Keep your diagnostic software updated to the latest version.

- Regular Maintenance: Inspect cables and connectors regularly for any signs of damage.

- Adequate Cooling: Ensure the ICOM NEXT has proper ventilation to prevent overheating.

10. Purchasing Guide: Where to Buy ICOM NEXT

When purchasing an ICOM NEXT, consider these factors:

- Reputable Suppliers: Buy from reputable suppliers like VCCarTool to ensure you receive a genuine product.

- Warranty: Check for warranty options to protect your investment.

- Customer Support: Ensure the supplier offers reliable customer support.

For a reliable purchase, contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 or email at [email protected]. Visit our website at vccartool.com for more information.

11. How VCCarTool Can Help You

At VCCarTool, we understand the challenges faced by automotive technicians. We offer:

- Expert Guidance: Our team provides expert advice to help you choose the right diagnostic tools.

- Quality Products: We offer high-quality ICOM NEXT interfaces and related accessories.

- Technical Support: We provide comprehensive technical support to assist you with setup and troubleshooting.

- Competitive Pricing: We offer competitive pricing to ensure you get the best value for your investment.

Contact VCCarTool today via WhatsApp: +1 (901) 414 – 1927 for personalized assistance.

12. Integrating ICOM NEXT into Your Workshop Workflow

Effectively integrating the ICOM NEXT into your workshop can streamline operations and improve diagnostic accuracy.

- Training: Ensure all technicians are properly trained on using the ICOM NEXT.

- Standard Procedures: Develop standard procedures for diagnostic and programming tasks.

- Data Management: Implement a system for managing diagnostic data and vehicle history.

- Regular Audits: Conduct regular audits of your diagnostic processes to identify areas for improvement.

13. Future Trends in BMW Diagnostics

Staying ahead of the curve is essential in the automotive industry. Here are some future trends in BMW diagnostics:

- Remote Diagnostics: Increased use of remote diagnostic services.

- AI-Powered Diagnostics: Integration of artificial intelligence for faster and more accurate diagnostics.

- Cloud-Based Solutions: Shift towards cloud-based diagnostic platforms.

- Advanced Driver-Assistance Systems (ADAS): Growing focus on ADAS calibration and diagnostics.

14. Benefits of Wireless Diagnostics

Wireless connectivity offers several advantages in automotive diagnostics:

- Flexibility: Technicians can move freely around the vehicle.

- Efficiency: Reduced cable clutter improves workflow.

- Safety: Eliminates tripping hazards.

- Accessibility: Easier access to hard-to-reach areas of the vehicle.

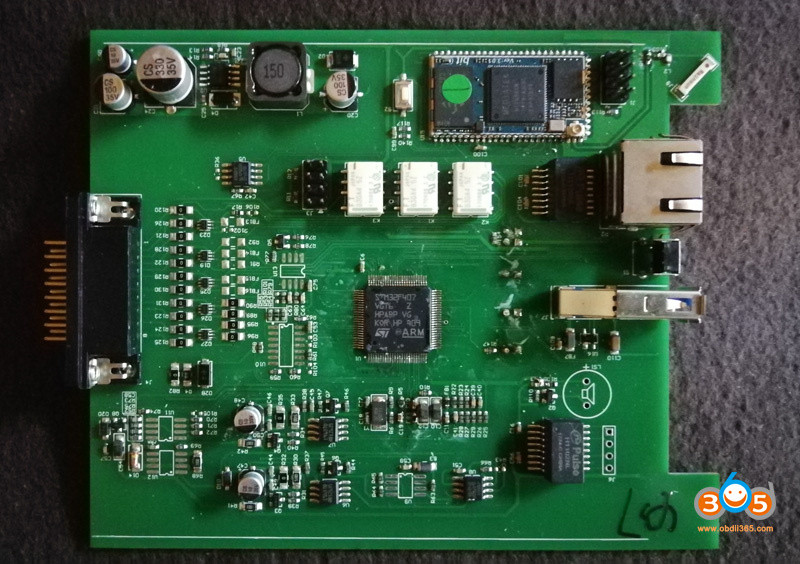

Bmw Icom Next Sp269 B1 1

Bmw Icom Next Sp269 B1 1

The BMW ICOM Next SP269 B1 showcasing its robust build and components.

15. The Role of Coding and Programming in Modern BMW Repair

Coding and programming are integral to modern BMW repair. Here’s why:

- Module Replacement: Coding is required when replacing electronic modules.

- Software Updates: Programming updates ECU software to improve performance and fix bugs.

- Customization: Coding allows customization of vehicle features and options.

- Retrofitting: Enables the addition of new features not originally installed in the vehicle.

16. The Importance of Choosing the Right Diagnostic Software

Selecting the correct diagnostic software is as crucial as choosing the right hardware. Key considerations include:

- Compatibility: Ensure the software is compatible with your ICOM NEXT interface.

- Functionality: Verify the software supports the diagnostic and programming tasks you need to perform.

- Updates: Choose software that receives regular updates to support new vehicle models and features.

- User Interface: Opt for software with an intuitive and user-friendly interface.

17. Protecting Your Investment: Maintenance Tips for ICOM NEXT

Proper maintenance extends the lifespan of your ICOM NEXT:

- Storage: Store the interface in a clean and dry environment.

- Cable Care: Avoid bending or kinking cables.

- Cleaning: Clean the interface and cables with a soft, dry cloth.

- Regular Inspections: Inspect the interface and cables regularly for any signs of damage.

18. Case Studies: Real-World Applications of ICOM NEXT

Here are examples of how the ICOM NEXT has been used in real-world scenarios:

- Fault Code Diagnosis: Quickly identifying and resolving complex fault codes in a BMW 5 Series.

- Module Programming: Successfully programming a new ECU in a BMW X5 after a replacement.

- Software Updates: Updating the transmission control module (TCM) in a BMW 3 Series to improve shifting performance.

- Custom Coding: Enabling hidden features, such as enhanced Bluetooth functionality, in a BMW 7 Series.

19. Understanding BMW Diagnostic Protocols

Familiarizing yourself with BMW diagnostic protocols enhances your diagnostic capabilities:

- OBD-II: Standard protocol for basic diagnostics.

- ISTA-D: Used for advanced diagnostics and fault code analysis.

- ISTA-P: Used for module programming and software updates.

- E-SYS: Used for coding and customizing vehicle features.

20. How to Update BMW Diagnostic Software: A Step-by-Step Guide

Keeping your diagnostic software up-to-date is essential for accurate and efficient BMW maintenance. Here’s a step-by-step guide to updating your BMW diagnostic software:

- Backup Your Current Configuration: Before starting any update, back up your current software configuration. This ensures that you can revert to your previous setup if anything goes wrong during the update.

- Check for Updates: Open your diagnostic software (e.g., ISTA-D, ISTA-P, or E-SYS) and look for an “Update” or “Check for Updates” option in the main menu or settings.

- Download the Latest Version: Once you find the update option, the software will search for available updates. Download the latest version of the software. Ensure you have a stable internet connection to avoid interruptions during the download.

- Install the Update: After the download is complete, follow the on-screen prompts to install the update. This usually involves agreeing to the terms and conditions and selecting an installation directory.

- Restart Your Computer: After the installation, restart your computer to ensure all the new files and settings are properly loaded.

- Verify the Installation: Open the updated software and check the version number to confirm that the update was successful.

- Test the Software: Connect the ICOM NEXT interface to your BMW vehicle and run a diagnostic test to ensure everything is working as expected.

21. FAQ: Common Questions About ICOM NEXT

Here are some frequently asked questions about the ICOM NEXT:

- What is the ICOM NEXT? The ICOM NEXT is a diagnostic and programming interface for BMW vehicles, enabling technicians to perform advanced diagnostics and module programming.

- Is the ICOM NEXT compatible with all BMW models? It supports a wide range of BMW models, including older and newer vehicles.

- What software does the ICOM NEXT work with? It works with ISTA-D, ISTA-P, E-SYS, INPA, WinKFP, and other diagnostic software.

- Can I use the ICOM NEXT for coding? Yes, it supports coding and customization of vehicle features.

- How do I update the firmware on the ICOM NEXT? Use the VX Manager software to check for and install firmware updates.

- What are the advantages of using a wireless connection? Wireless connectivity provides flexibility, reduces cable clutter, and improves accessibility.

- Where can I buy a genuine ICOM NEXT? Purchase from reputable suppliers like VCCarTool to ensure you receive a quality product. Contact us via WhatsApp: +1 (901) 414 – 1927 for assistance.

- What is the difference between SP269-B1 and SP269-D? SP269-B1 is a higher-quality clone with broader compatibility, while SP269-D is a more affordable option using the VXDIAG solution.

- How often should I update the firmware on my ICOM NEXT? Check for updates regularly and install them as soon as they are available to ensure optimal performance.

- What should I do if I encounter connection problems with my ICOM NEXT? Check cable connections, verify Ethernet or Wi-Fi settings, and ensure the correct IP address is configured. Contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for further support.

22. Call to Action

Ready to elevate your BMW diagnostic capabilities? Contact VCCarTool today for expert guidance and high-quality ICOM NEXT interfaces. Our team is here to help you choose the right tools and provide comprehensive support.

Don’t wait – enhance your workshop’s efficiency and accuracy now. Reach out to VCCarTool via:

- WhatsApp: +1 (901) 414 – 1927

- Email: [email protected]

- Website: vccartool.com

Let VCCarTool be your trusted partner in BMW diagnostics and programming. We look forward to assisting you! If you have any concerns when referring to the article, please contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for the fastest FREE support.

Bmw Icom Next Clone Sp269 1

Bmw Icom Next Clone Sp269 1

The BMW ICOM Next Clone SP269 1 showcasing its essential components and connectivity ports.