3406E vs C15: Which Caterpillar Engine is Right for You?

Choosing the right diesel engine can be tough. This article provides a detailed comparison of the Caterpillar 3406E and C15 engines, highlighting their unique features, common issues, and specifications to help you make an informed decision. VCCarTool equips you with the knowledge to choose the best engine for your needs, ensuring optimal performance and longevity. Learn about engine diagnostics, engine programming, and troubleshooting.

1. Caterpillar 3406E: A Legacy of Reliability

The Caterpillar 3406E is renowned for its reliability and has been a favorite among mechanics for years. Introduced in 1993, it was the first fully electronic engine in the 3406 series, succeeding the semi-electronic 3406C.

Before the 3406E, Caterpillar released several iterations of the 3406 engine, including the 3406A, 3406B, and 3406C. The 3406A and 3406B were fully mechanical engines, while the 3406C introduced some electronic functions to the fuel pump but remained primarily mechanical. The 3406E was the first fully electronic motor that delivered exceptional performance, making it a popular choice for various applications even today.

1.1. Common Caterpillar 3406E Problems

Despite its robust design, the Caterpillar 3406E is not without its issues. One common problem is oil leaks, particularly near the rear side of the engine around the spacer plate and cylinder block. These leaks were often attributed to poor-quality gaskets used during the early production runs of the 3406E. While Caterpillar addressed this issue in later models, it remained a concern for older engines. Another cause of oil leaks is the hardening of rubber plugs near the back of the engine block due to aging.

The age of the engine plays a significant role in the occurrence of these problems. While the 3406E was considered an unbeatable engine in its prime, time can exacerbate these issues.

oil leak quart juggs

oil leak quart juggs

1.2. Caterpillar 3406E Engine Specifications

Here are the key specifications for the Caterpillar 3406E engine:

| Specification | Detail |

|---|---|

| Fuel | Diesel |

| Liter | 14.6 |

| Cubic Inch Displacement | 893 |

| Cylinder Bore Diameter | 5.4000-5.4020″ (137.16-137.211 MM) |

| Stroke | 6.500″ (165.1 MM) |

| Cylinder Configuration | L6 |

| Engine Comments | 3406E truck, OHC, 24 Valve |

2. Caterpillar C15: An Enhanced Successor

Introduced in 1999 as a successor to the 3406E, the Caterpillar C15 quickly gained popularity due to its reliability and versatility. Caterpillar lists over 34 applications powered by this engine, including combines, harvesters, paving equipment, pumps, earth-moving equipment, and aircraft support.

The C15 was designed to improve upon the 3406E, featuring upgraded gaskets and better seals to address the oil leaks that plagued earlier models. VCCarTool offers a wide range of high-quality parts for the C15.

2.1. Caterpillar C15 Still in Production?

Yes, the Caterpillar C15 is still available for installation in most kits. However, availability can affect build time. Contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for the latest information on C15 availability and options.

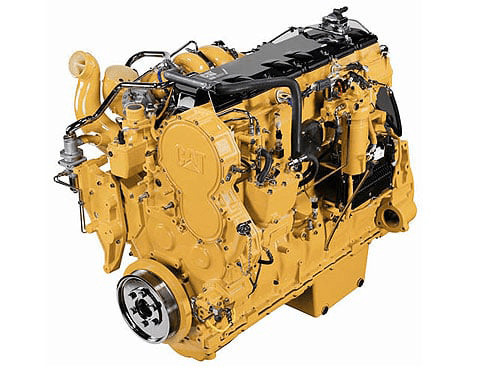

cat c15 engine

cat c15 engine

2.2. Common Caterpillar C15 Problems

While the C15 was designed to be an improvement over the 3406E, it did have its own set of issues. To prevent pressure on the gaskets, Caterpillar introduced relief slots on the cylinder head. However, this change led to more frequent gasket failures. Using high-quality gaskets, built to strict OEM specifications, can solve this issue. VCCarTool provides a selection of C15 gaskets designed for proper fit and function.

The C15’s MBN prefix, released between 2002 and 2003, earned the nickname “Much Bad News” due to its high operating temperatures, excessive fuel consumption, and poor pulling power.

2.2.1. Is the Cat C15 a Good Motor?

The Caterpillar C15 engine is generally considered a good and reliable engine. One of the key improvements over the 3406E is reduced oil leakage.

2.3. Caterpillar C15 Engine Specifications

Here are the key specifications for the Caterpillar C15 engine:

| Specification | Detail |

|---|---|

| Fuel | Diesel |

| Liter | 15.2 |

| Cubic Inch Displacement | 928 |

| Cylinder Bore Diameter | 5.4000-5.4020″ (137.160-137.210 MM) |

| Stroke | 6.732″ (171.000 MM) |

| Cylinder Configuration | L6 |

| Engine Comments | Diesel SOHC Electronic, Similar To 3406E, Non-ACERT |

3. Caterpillar C15 ACERT: Meeting Emission Standards

In 2004, Caterpillar transitioned to the C15 ACERT (Advanced Combustion Emission Reduction Technology). This engine focused on the air and fuel systems to meet the strict EPA emission requirements set in 2002.

While some believe the primary difference between the C15 and C15 ACERT is the addition of a second turbocharger, there are other significant improvements. One notable enhancement is the piston design. The regular C15 features a two-piece aluminum skirt piston, while the ACERT has a one-piece steel design.

c15 acert engine caterpillar

c15 acert engine caterpillar

3.1. Caterpillar C15 ACERT Problems

When tuned correctly, the C15 ACERT can be a strong and reliable engine. However, early models had issues, including broken rocker studs. By now, most ACERTs have updated studs, mitigating this problem. The exhaust manifolds and their studs are also prone to breaking.

Age and fuel mileage can also affect the injectors, leading to failures over time. Proper maintenance is essential for ensuring the longevity and reliability of C15 ACERT engines.

3.2. Caterpillar C15 ACERT Engine Specifications

Here are the key specifications for the Caterpillar C15 ACERT engine:

| Specification | Detail |

|---|---|

| Fuel | Diesel |

| Liter | 15.2 |

| Cubic Inch Displacement | 928 |

| Cylinder Bore Diameter | 5.4000-5.4020″ (137.160-137.210 MM) |

| Stroke | 6.732″ (171.000 MM) |

| Cylinder Configuration | L6 |

| Engine Comments | Diesel SOHC Electronic, Similar To 3406E, ACERT |

4. Key Differences Between the 3406E, C15, and C15 ACERT

| Feature | Caterpillar 3406E | Caterpillar C15 | Caterpillar C15 ACERT |

|---|---|---|---|

| Production Years | 1993-1999 | 1999-2004 | 2004-Present |

| Electronic Components | Fully Electronic | Fully Electronic | Fully Electronic |

| Emissions Standards | Pre-EPA | Pre-EPA | EPA Compliant |

| Fuel System | Electronic Unit Injectors | Electronic Unit Injectors | Electronic Unit Injectors |

| Turbocharger | Single Turbocharger | Single Turbocharger | Single or Twin Turbochargers |

| Piston Design | Two-Piece Aluminum Skirt | Two-Piece Aluminum Skirt | One-Piece Steel |

| Common Problems | Oil Leaks | Gasket Failures, MBN Issues | Rocker Studs, Manifold Issues |

| Liter | 14.6 | 15.2 | 15.2 |

| Technology | Basic Electronic Control | Improved Electronic Control | ACERT Technology |

5. In-Depth Comparison: 3406E vs C15 vs C15 ACERT

To make an informed decision, let’s delve deeper into the key differences between these Caterpillar engines.

5.1. Reliability and Durability

- Caterpillar 3406E: Known for its robust design and reliability, the 3406E has stood the test of time. However, older models may experience oil leaks due to aging gaskets and rubber plugs.

- Caterpillar C15: Designed to improve upon the 3406E, the C15 features upgraded gaskets and seals to reduce oil leaks. However, early models had issues with gasket failures due to relief slots on the cylinder head.

- Caterpillar C15 ACERT: When properly maintained, the C15 ACERT is a strong and reliable engine. However, early models had issues with broken rocker studs and exhaust manifold failures.

5.2. Performance and Efficiency

- Caterpillar 3406E: Offers good performance and fuel efficiency for its time.

- Caterpillar C15: Provides improved performance and fuel efficiency compared to the 3406E.

- Caterpillar C15 ACERT: Designed to meet strict EPA emission standards, the C15 ACERT offers a balance of performance and environmental compliance.

5.3. Emission Compliance

- Caterpillar 3406E: Pre-EPA emission standards.

- Caterpillar C15: Pre-EPA emission standards.

- Caterpillar C15 ACERT: EPA compliant.

5.4. Maintenance and Repair

- Caterpillar 3406E: Relatively simple to maintain and repair due to its straightforward design.

- Caterpillar C15: Requires more specialized knowledge and tools for maintenance and repair due to its advanced electronic controls.

- Caterpillar C15 ACERT: Requires specialized knowledge and tools for maintenance and repair due to its ACERT technology and complex emission control systems. VCCarTool offers comprehensive diagnostic tools and software to help you maintain and repair these engines effectively.

5.5. Applications

- Caterpillar 3406E: Suitable for a wide range of applications, including trucks, construction equipment, and generators.

- Caterpillar C15: Versatile engine used in various applications, including combines, harvesters, paving equipment, and pumps.

- Caterpillar C15 ACERT: Ideal for applications requiring compliance with strict emission standards, such as on-highway trucks and heavy-duty equipment.

6. Choosing the Right Engine: Factors to Consider

Selecting the right Caterpillar engine depends on your specific needs and priorities. Consider the following factors:

- Application: Determine the primary use of the engine and select an engine that is well-suited for that application.

- Budget: Consider your budget for purchasing, maintaining, and repairing the engine.

- Emission Requirements: Ensure the engine meets the emission standards in your region.

- Performance Requirements: Evaluate the required power, torque, and fuel efficiency for your application.

- Maintenance Capabilities: Assess your ability to maintain and repair the engine or access to qualified technicians and resources. VCCarTool provides comprehensive support and resources to help you maintain your engine. Contact us via WhatsApp: +1 (901) 414 – 1927 for expert advice and assistance.

7. Diagnostic and Programming Tools for Caterpillar Engines

Effective diagnostics and programming are crucial for maintaining the performance and reliability of Caterpillar engines. VCCarTool offers a range of advanced diagnostic tools and software solutions to help you troubleshoot, repair, and optimize your engines.

7.1. Diagnostic Tools

VCCarTool provides a variety of diagnostic tools designed for Caterpillar engines, including:

- Caterpillar Electronic Technician (Cat ET): A comprehensive diagnostic software that allows you to communicate with the engine control module (ECM), view diagnostic codes, perform calibrations, and troubleshoot issues.

- мультитул VCCarTool Handheld Diagnostic Scanners: Portable and user-friendly scanners that allow you to quickly read and clear diagnostic codes, view live engine data, and perform basic diagnostics.

- VCCarTool Data Loggers: Devices that record engine data over time, allowing you to analyze performance trends, identify intermittent issues, and optimize engine parameters.

7.2. Programming Software

VCCarTool offers programming software to customize engine parameters, optimize performance, and ensure compliance with emission standards. Our programming solutions include:

- Caterpillar Flash Files: Calibrated software files that can be flashed to the ECM to update engine parameters, improve performance, and address specific issues.

- VCCarTool Custom Tuning Software: Advanced software that allows you to fine-tune engine parameters, such as fuel injection timing, turbocharger boost, and air-fuel ratio, to optimize performance and fuel efficiency.

7.3. Benefits of Using VCCarTool Diagnostic and Programming Tools

- Accurate Diagnostics: Identify and diagnose engine issues quickly and accurately.

- Efficient Repairs: Streamline the repair process and reduce downtime.

- Optimized Performance: Fine-tune engine parameters to maximize performance and fuel efficiency.

- Emission Compliance: Ensure your engine meets emission standards and regulations.

- Cost Savings: Reduce maintenance costs and extend the life of your engine.

8. Troubleshooting Common Issues

Addressing common issues promptly can prevent costly repairs and downtime. Here are some troubleshooting tips for the 3406E, C15, and C15 ACERT engines:

8.1. Oil Leaks (3406E and C15)

- Inspect Gaskets and Seals: Check for worn or damaged gaskets and seals around the cylinder head, spacer plate, and oil pan.

- Replace Rubber Plugs: Replace hardened rubber plugs near the back of the engine block.

- Use High-Quality Gaskets: Use high-quality OEM-specified gaskets for replacements.

8.2. Gasket Failures (C15)

- Inspect Cylinder Head: Check the cylinder head for cracks or damage.

- Use High-Quality Gaskets: Use high-quality gaskets designed to withstand high pressures and temperatures.

- Ensure Proper Installation: Follow the manufacturer’s installation instructions carefully.

8.3. Rocker Stud Failures (C15 ACERT)

- Inspect Rocker Studs: Check for broken or damaged rocker studs.

- Replace with Updated Studs: Replace with updated, heavy-duty rocker studs.

- Ensure Proper Torque: Ensure rocker studs are torqued to the manufacturer’s specifications.

8.4. Exhaust Manifold Failures (C15 ACERT)

- Inspect Exhaust Manifolds: Check for cracks or warping.

- Replace Manifolds and Studs: Replace damaged manifolds and studs with high-quality replacements.

- Ensure Proper Torque: Ensure manifold studs are torqued to the manufacturer’s specifications.

8.5. Injector Failures (C15 ACERT)

- Test Injectors: Use diagnostic tools to test injector performance.

- Clean or Replace Injectors: Clean or replace faulty injectors as needed.

- Use High-Quality Fuel Filters: Use high-quality fuel filters to prevent contamination.

9. Maintenance Best Practices

Regular maintenance is key to ensuring the longevity and reliability of your Caterpillar engine. Follow these best practices:

- Regular Oil Changes: Change the engine oil and filter at the recommended intervals.

- Inspect Air Filter: Inspect and replace the air filter regularly to ensure proper airflow.

- Check Coolant Levels: Check and maintain proper coolant levels to prevent overheating.

- Inspect Hoses and Belts: Inspect hoses and belts for cracks, wear, and damage.

- Monitor Engine Performance: Use diagnostic tools to monitor engine performance and identify potential issues early.

10. Real-World Case Studies

Case Study 1: Trucking Company

- Challenge: A trucking company with a fleet of Caterpillar 3406E engines experienced frequent oil leaks, leading to increased maintenance costs and downtime.

- Solution: VCCarTool recommended replacing the worn gaskets and rubber plugs with high-quality OEM replacements. The company also implemented a regular maintenance schedule, including oil changes and inspections.

- Result: The company reduced oil leaks by 80%, decreased maintenance costs, and improved fleet reliability.

Case Study 2: Construction Firm

- Challenge: A construction firm with Caterpillar C15 ACERT engines experienced exhaust manifold failures, leading to reduced engine performance and increased downtime.

- Solution: VCCarTool recommended replacing the exhaust manifolds and studs with high-quality replacements. The firm also implemented a regular inspection schedule to identify potential issues early.

- Result: The firm reduced exhaust manifold failures by 70%, improved engine performance, and decreased downtime.

11. Expert Insights and Recommendations

To gain further insights, we consulted with experienced mechanics and Caterpillar engine specialists. Here are some key recommendations:

- Choose the Right Engine for Your Application: Carefully consider your specific needs and priorities when selecting an engine.

- Prioritize Maintenance: Implement a regular maintenance schedule to ensure the longevity and reliability of your engine.

- Use High-Quality Parts: Use high-quality OEM-specified parts for replacements to ensure proper fit and performance.

- Invest in Diagnostic Tools: Invest in diagnostic tools to monitor engine performance and identify potential issues early.

- Seek Expert Advice: Consult with experienced mechanics and Caterpillar engine specialists for advice and support.

12. FAQs: Caterpillar 3406E vs C15

-

What is the main difference between the Caterpillar 3406E and C15?

The C15 was designed to improve upon the 3406E, featuring upgraded gaskets and seals to address oil leaks. -

Which engine is more reliable, the 3406E or C15?

Both are reliable, but the C15 has improvements to reduce oil leaks compared to the 3406E. -

What is ACERT technology?

ACERT (Advanced Combustion Emission Reduction Technology) is a Caterpillar technology focused on reducing emissions by optimizing air and fuel systems. -

What are the common problems with the C15 ACERT engine?

Common issues include broken rocker studs and exhaust manifold failures in early models. -

How can I troubleshoot oil leaks in my 3406E engine?

Inspect gaskets and seals, replace rubber plugs, and use high-quality OEM gaskets for replacements. -

What diagnostic tools are recommended for Caterpillar engines?

Caterpillar Electronic Technician (Cat ET) and VCCarTool Handheld Diagnostic Scanners are recommended. -

How often should I change the oil in my Caterpillar engine?

Follow the manufacturer’s recommended intervals for oil changes. -

What are the benefits of using custom tuning software for Caterpillar engines?

Custom tuning software allows you to fine-tune engine parameters to optimize performance and fuel efficiency. -

How can I ensure my Caterpillar engine meets emission standards?

Use Caterpillar Flash Files and ensure your engine is properly maintained and tuned. -

Where can I find reliable parts and support for my Caterpillar engine?

VCCarTool offers a wide range of high-quality parts and comprehensive support for Caterpillar engines. Contact us via WhatsApp: +1 (901) 414 – 1927.

13. Get Expert Assistance from VCCarTool

Choosing the right engine and maintaining it properly is crucial for your business. VCCarTool is here to help you every step of the way.

13.1. Need Help with Diagnostics or Repairs?

Our team of experienced technicians can provide expert assistance with diagnostics, repairs, and maintenance for your Caterpillar engines. We offer a range of services, including:

- Engine Diagnostics: Accurate and efficient diagnostics to identify and troubleshoot engine issues.

- Engine Repairs: High-quality repairs using OEM-specified parts and proven techniques.

- Preventive Maintenance: Comprehensive maintenance services to keep your engines running smoothly and prevent costly breakdowns.

- Custom Tuning: Custom tuning services to optimize engine performance and fuel efficiency.

13.2. Contact Us Today

Don’t let engine problems slow you down. Contact VCCarTool today for expert assistance and reliable solutions.

- WhatsApp: +1 (901) 414 – 1927

- Email: [email protected]

- Website: vccartool.com

14. Act Now: Optimize Your Engine Performance!

Ready to take your engine’s performance to the next level? Contact VCCarTool now to learn more about our diagnostic tools, programming software, and expert services. Our team is standing by to help you choose the right solutions for your needs and ensure your engines are running at their best. Don’t wait – contact us today and experience the VCCarTool difference! WhatsApp: +1 (901) 414 – 1927.

Whether you’re deciding between a 3406E, C15, or C15 ACERT, remember that VCCarTool is your trusted partner for all your engine diagnostic, repair, and performance needs. Contact us today and let us help you keep your engines running strong!