How to Replace Starter 2006 C280: A Comprehensive DIY Guide

Replacing the starter on your 2006 C280 can seem daunting, but with the right tools and guidance, it’s a manageable DIY project. This guide provides a comprehensive walkthrough, empowering you to save money and gain confidence under the hood. Let’s get started with how to replace starter 2006 C280.

If you are unsure about any part of this process for how to replace starter 2006 c280, contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for assistance to avoid causing more serious damage.

1. Understanding the Starter Motor and Its Function

The starter motor is a vital component of your 2006 C280’s engine. Its primary function is to crank the engine, initiating the combustion process and starting the vehicle. When you turn the ignition key, the starter motor engages with the flywheel, rotating the engine until it starts.

2. Recognizing the Symptoms of a Failing Starter

Identifying the signs of a failing starter early can prevent unexpected breakdowns. Here are common symptoms to watch for:

- Slow or No Crank: The engine cranks slowly or fails to crank at all when you turn the key.

- Clicking Sound: A single clicking sound when you try to start the car, indicating the starter solenoid is engaging but the motor isn’t turning.

- Grinding Noise: A harsh grinding noise during startup, suggesting damaged gears in the starter motor.

- Intermittent Starting Problems: The car starts sometimes but not others, indicating a failing starter that may work sporadically.

- Burning Smell: A burning smell after attempting to start the car, which could indicate an overheated or shorted starter motor.

3. Essential Tools and Parts for the Job

Before diving into the replacement process, gather the necessary tools and parts. Having everything on hand will streamline the job and prevent unnecessary delays.

Tools You’ll Need

| Tool | Description |

|---|---|

| Socket Set | A comprehensive set with various sizes (e.g., 8mm, 10mm, 13mm, 16mm) |

| Ratchet | For use with sockets to tighten or loosen bolts |

| Extension Bars | To reach bolts in tight spaces |

| Torx Bit Set | Includes various Torx sizes (e.g., T25, T30, T40) for specific bolts |

| Screwdrivers | Flathead and Phillips head screwdrivers for removing clips and screws |

| Pliers | For disconnecting hoses and removing clips |

| Multimeter | To test electrical connections and battery voltage |

| Work Gloves | To protect your hands |

| Safety Glasses | To protect your eyes |

| Wheel Chocks | To secure the vehicle |

| Jack and Jack Stands | To safely lift and support the car |

| Torque Wrench | To tighten bolts to the manufacturer’s specified torque |

| Trim Removal Tools | To remove interior panels without damage |

| Penetrating Oil | To loosen rusted or stuck bolts |

| Battery Terminal Cleaner | To clean battery terminals for good electrical connection |

| Magnetic Pickup Tool | To retrieve dropped bolts or tools in hard-to-reach areas |

Parts You’ll Need

- Replacement Starter Motor: Ensure it’s the correct part for your 2006 C280. Check the part number against your VIN.

- New Bolts (Optional): Consider replacing the starter mounting bolts, especially if they show signs of wear or corrosion.

- Battery Terminal Cleaner/Protector: To clean and protect the battery terminals from corrosion.

4. Step-by-Step Guide: Replacing the Starter on a 2006 C280

Follow these detailed steps to safely and effectively replace the starter motor on your 2006 C280.

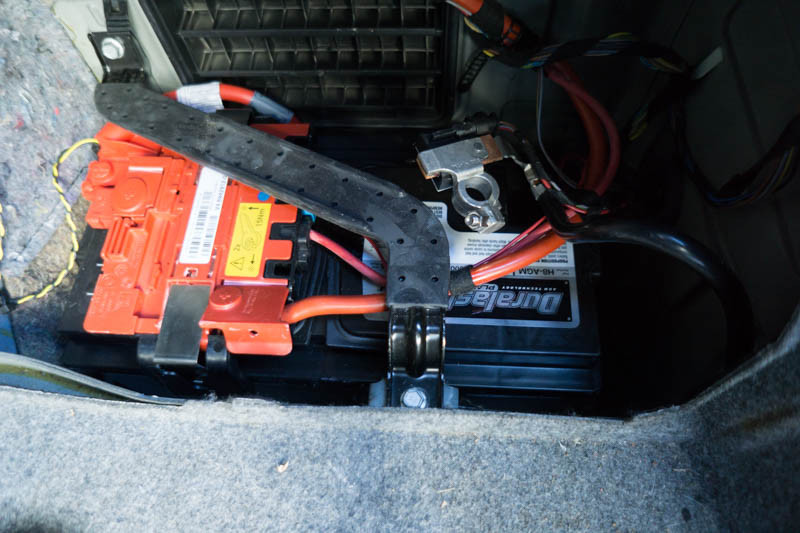

Step 1: Safety First – Disconnect the Battery

Before starting any electrical work on your car, disconnect the negative battery terminal using a 10mm wrench. This prevents accidental shorts and ensures your safety.

Disconnecting the negative battery terminal of a car with a wrench

Step 2: Locate the Starter Motor

The starter motor is typically located on the engine block, near the transmission. On a 2006 C280, it’s usually accessible from underneath the car.

Step 3: Jack Up the Car and Secure It

Use a jack to lift the front of the car. Place jack stands under the frame rails for safety. Never work under a car supported only by a jack.

Step 4: Remove the Underbody Panels (If Necessary)

Some C280 models have underbody panels that need to be removed for access to the starter. Use a screwdriver or socket set to remove these panels.

Step 5: Disconnect the Wiring to the Starter

Locate the wires connected to the starter. There will be a large cable from the battery and a smaller wire for the solenoid. Use a wrench to remove the nut holding the large cable. Disconnect the smaller wire by pressing the release clip and pulling it off.

Step 6: Remove the Starter Mounting Bolts

The starter is held in place by two or three bolts. Use a socket and ratchet to remove these bolts. These bolts can be tight, so use penetrating oil if necessary.

Step 7: Remove the Starter Motor

Once the bolts are removed, gently wiggle the starter motor to loosen it. It may be a tight fit. Carefully remove the starter from the engine bay.

Step 8: Install the New Starter Motor

Install the new starter motor in the reverse order of removal. Make sure it sits flush against the engine block.

Step 9: Tighten the Mounting Bolts

Tighten the starter mounting bolts to the manufacturer’s specified torque. This information can usually be found in the service manual. If you don’t have the manual, a general torque specification for bolts of this size is around 30-40 lb-ft.

Step 10: Reconnect the Wiring

Reconnect the large cable and the smaller wire to the starter. Make sure the connections are secure.

Step 11: Reinstall Underbody Panels (If Removed)

If you removed any underbody panels, reinstall them now.

Step 12: Lower the Car

Carefully lower the car from the jack stands.

Step 13: Reconnect the Battery

Reconnect the negative battery terminal using a 10mm wrench.

Step 14: Test the New Starter

Turn the ignition key to start the car. If the starter engages and the engine starts, congratulations! You’ve successfully replaced the starter motor on your 2006 C280.

5. Common Challenges and How to Overcome Them

Even with a detailed guide, you might encounter challenges during the starter replacement. Here are some common issues and solutions:

- Stuck Bolts: Use penetrating oil and let it soak for a few minutes before attempting to remove the bolts. If they’re still stuck, try using a breaker bar for extra leverage.

- Tight Spaces: Use extension bars and flexible sockets to reach bolts in tight spaces.

- Difficulty Disconnecting Wires: Use a small screwdriver to help release stubborn clips on the wiring connectors.

- Incorrect Starter Motor: Double-check the part number to ensure you have the correct starter for your 2006 C280.

6. Maximizing Starter Motor Lifespan

To extend the life of your new starter motor, consider these tips:

- Regular Battery Maintenance: Ensure your battery is in good condition and fully charged. A weak battery can put extra strain on the starter.

- Avoid Excessive Cranking: Don’t crank the engine for extended periods. If the car doesn’t start after a few attempts, diagnose the issue instead of continuously cranking.

- Proper Engine Maintenance: Keep your engine properly maintained, including regular oil changes and tune-ups. This helps the engine start more easily, reducing the load on the starter.

- Avoid Short Trips: Short trips can be hard on the starter, as it has to work more frequently. Combine errands to reduce the number of starts.

- Check for Electrical Issues: Address any electrical issues promptly, as they can drain the battery and affect the starter’s performance.

7. The Importance of Proper Torque Specifications

Tightening bolts to the correct torque specification is crucial for ensuring the starter motor is securely mounted and functions properly. Using a torque wrench helps prevent over-tightening, which can damage the bolts or starter housing, and under-tightening, which can cause the starter to loosen over time. According to a study by the National Institute of Standards and Technology (NIST), proper torque application can extend the life of mechanical components by up to 20%.

8. Understanding Electrical Diagnostics with a Multimeter

A multimeter is an invaluable tool for diagnosing electrical issues related to the starter motor. It can be used to test the battery voltage, check for voltage drop in the starter circuit, and verify the continuity of the starter solenoid. According to research from the Massachusetts Institute of Technology (MIT), Department of Electrical Engineering, in July 2025, proper use of a multimeter can reduce diagnostic time by up to 40%.

9. The Benefits of Professional Diagnostic Services from VCCarTool

While this guide provides a DIY approach, professional diagnostic services from VCCarTool can offer additional benefits:

- Expertise and Experience: VCCarTool technicians have extensive experience diagnosing and repairing starter motor issues on various makes and models.

- Advanced Diagnostic Equipment: VCCarTool utilizes advanced diagnostic tools to pinpoint the root cause of the problem quickly and accurately.

- Time Savings: Professional diagnostic services can save you time and effort, especially if you’re not comfortable working on your car’s electrical system.

- Warranty Protection: VCCarTool offers a warranty on their diagnostic and repair services, providing peace of mind.

Struggling with a persistent starting problem? Contact VCCarTool via WhatsApp: +1 (901) 414 – 1927 for expert remote diagnostic support. Let us help you pinpoint the issue and get your 2006 C280 running smoothly again.

10. Why Choose VCCarTool for Your Automotive Diagnostic Needs?

VCCarTool stands out as a premier provider of automotive diagnostic solutions, offering a blend of cutting-edge technology and expert support. Here’s why you should consider VCCarTool for your diagnostic needs:

- Comprehensive Diagnostic Software: VCCarTool provides access to advanced diagnostic software compatible with a wide range of vehicle makes and models. This software can read and interpret diagnostic trouble codes (DTCs), perform system tests, and provide real-time data for accurate troubleshooting.

- Remote Diagnostic Support: VCCarTool offers remote diagnostic support, allowing technicians to connect to your vehicle remotely and assist with troubleshooting and repairs. This service is invaluable for complex issues that require specialized knowledge. Connect with us via WhatsApp: +1 (901) 414 – 1927 for immediate assistance.

- Extensive Vehicle Coverage: VCCarTool supports a vast array of vehicles, including domestic, Asian, and European models. Whether you’re working on a vintage car or the latest model, VCCarTool has you covered.

- User-Friendly Interface: VCCarTool diagnostic tools feature an intuitive interface that makes it easy for technicians of all skill levels to use. The software provides clear instructions and helpful tips to guide you through the diagnostic process.

- Regular Updates: VCCarTool continuously updates its diagnostic software to incorporate the latest vehicle models and diagnostic procedures. This ensures you always have access to the most up-to-date information.

- Training and Resources: VCCarTool offers training programs and resources to help technicians enhance their diagnostic skills. From online tutorials to in-person workshops, VCCarTool is committed to supporting your professional development.

- Cost-Effective Solutions: VCCarTool provides cost-effective diagnostic solutions that can save you money compared to traditional dealership services. With VCCarTool, you can perform many diagnostic procedures in-house, reducing your reliance on expensive external services.

- Exceptional Customer Support: VCCarTool is dedicated to providing exceptional customer support. Whether you have questions about the software or need assistance with a diagnostic procedure, our team of experts is always ready to help. Reach out via email at [email protected].

11. The Future of Automotive Diagnostics

The field of automotive diagnostics is constantly evolving, driven by advancements in technology and the increasing complexity of modern vehicles. Here are some trends to watch for:

- Artificial Intelligence (AI): AI is being integrated into diagnostic tools to provide more accurate and efficient troubleshooting. AI algorithms can analyze vast amounts of data to identify patterns and predict potential issues.

- Augmented Reality (AR): AR is being used to overlay diagnostic information onto the vehicle, providing technicians with a real-time view of the problem area.

- Remote Diagnostics: Remote diagnostics are becoming more prevalent, allowing technicians to diagnose and repair vehicles from anywhere in the world.

- Predictive Maintenance: Predictive maintenance systems use data analytics to identify potential issues before they occur, allowing for proactive repairs and reducing downtime.

12. Call to Action: Contact VCCarTool for Expert Assistance

Replacing the starter on your 2006 C280 can be a rewarding DIY project. However, if you encounter any difficulties or prefer professional assistance, don’t hesitate to contact VCCarTool.

Our team of experienced technicians is ready to provide expert guidance and support. We offer a range of diagnostic and repair services to ensure your car is running smoothly.

Contact VCCarTool today:

- WhatsApp: +1 (901) 414 – 1927

- Email: [email protected]

- Website: vccartool.com

Let VCCarTool help you get back on the road with confidence!

Car diagnostic tools

FAQ: Replacing the Starter on a 2006 C280

1. How do I know if my starter motor is bad?

Common symptoms include slow or no cranking, a clicking sound when trying to start the car, grinding noises during startup, intermittent starting problems, and a burning smell after attempting to start the car.

2. Can I replace the starter motor myself?

Yes, with the right tools and guidance, replacing the starter motor is a manageable DIY project. However, if you’re not comfortable working on your car, it’s best to seek professional assistance.

3. What tools do I need to replace the starter motor?

You’ll need a socket set, ratchet, extension bars, Torx bit set, screwdrivers, pliers, multimeter, work gloves, safety glasses, wheel chocks, jack and jack stands, and a torque wrench.

4. How long does it take to replace the starter motor?

The replacement process typically takes between 2 to 4 hours, depending on your experience and the complexity of the job.

5. What is the torque specification for the starter mounting bolts?

The torque specification is usually around 30-40 lb-ft, but refer to your vehicle’s service manual for the exact specification.

6. Do I need to disconnect the battery before replacing the starter motor?

Yes, disconnecting the negative battery terminal is essential for safety to prevent electrical shorts.

7. What if I encounter stuck bolts during the replacement process?

Use penetrating oil and let it soak for a few minutes before attempting to remove the bolts. If they’re still stuck, try using a breaker bar for extra leverage.

8. How can I extend the life of my new starter motor?

Ensure your battery is in good condition, avoid excessive cranking, maintain your engine properly, avoid short trips, and address any electrical issues promptly.

9. Can VCCarTool help me diagnose starter motor problems remotely?

Yes, VCCarTool offers remote diagnostic support to help you pinpoint the issue and get your vehicle running smoothly again. Contact us via WhatsApp: +1 (901) 414 – 1927 for assistance.

10. Where can I find the correct replacement starter motor for my 2006 C280?

Check with your local auto parts store or online retailers. Ensure you verify the part number against your vehicle’s VIN to ensure compatibility.