How Does a Speedometer Sensor Work?

Welcome to your ultimate guide on understanding exactly how a speedometer sensor works. This crucial component is the unsung hero behind accurate speed readings, and knowing its intricacies can significantly boost your diagnostic skills and repair efficiency. At VCCarTool, we understand your need for reliable information and top-notch tools, and we’re here to provide both. Let’s dive into the fascinating world of speed sensors and explore how they contribute to a smooth and safe driving experience. Discover the technology behind these vital devices and how they communicate crucial data to your vehicle’s systems.

For those looking to enhance their garage capabilities, remember that VCCarTool offers a wide range of diagnostic tools and equipment designed to make your work easier and more profitable.

1. Unveiling the Mystery: What is a Speedometer Sensor?

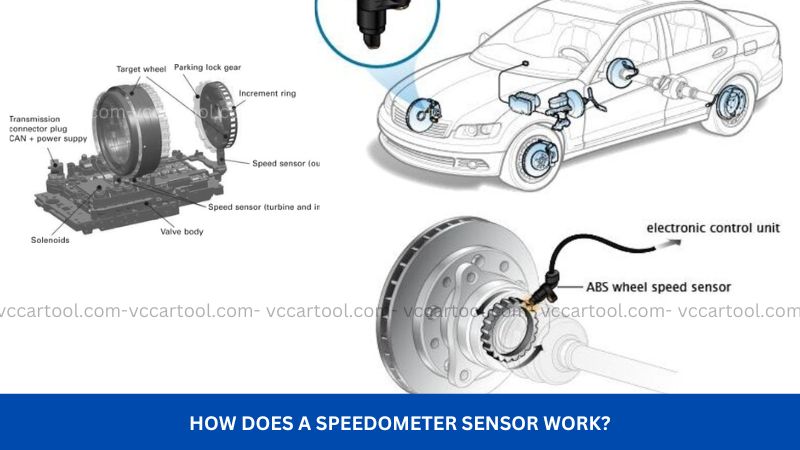

A speedometer sensor, often called a Vehicle Speed Sensor (VSS), is an electronic device in your vehicle responsible for measuring the rotational speed of a component within the drivetrain. This information is then transmitted as an electrical signal to the speedometer, displaying your current speed to the driver. But its role extends far beyond just the dashboard reading. The data from the VSS is also crucial for other vehicle systems, including the engine control unit (ECU), transmission control unit (TCU), anti-lock braking system (ABS), and cruise control system. Accurate speed readings ensure these systems function optimally, contributing to overall vehicle performance, safety, and efficiency.

2. The Inner Workings: How Speedometer Sensors Operate.

The fundamental principle behind a speedometer sensor’s operation involves detecting movement and converting it into an electrical signal. While there are different types of speed sensors, they generally rely on electromagnetic induction or the Hall effect. Let’s explore the two most common types:

2.1 Reluctance or Inductive Speed Sensors.

These sensors utilize the principle of electromagnetic induction. They typically consist of a stationary coil of wire and a rotating toothed wheel (reluctor ring) attached to a rotating part of the drivetrain, such as the transmission output shaft or a wheel hub.

- The Process. As the toothed wheel rotates, the teeth pass by the sensor’s magnetic pole. Each passing tooth disrupts the magnetic field, causing a change in the magnetic flux through the coil. This change in flux induces a small alternating current (AC) voltage in the coil. The frequency of this AC signal is directly proportional to the rotational speed of the toothed wheel. The faster the wheel spins, the more teeth pass the sensor per unit of time, resulting in a higher frequency signal.

- Signal Interpretation. The ECU or another control module receives this AC signal and interprets its frequency to determine the vehicle’s speed. A higher frequency translates to a higher speed, and a lower frequency indicates a slower speed. The amplitude of the signal can also sometimes be used for diagnostic purposes.

2.2 Hall Effect Speed Sensors.

Hall effect sensors employ a semiconductor material that produces a voltage difference (the Hall voltage) when a magnetic field is applied perpendicular to the direction of current flow within the material. These sensors typically work with a rotating target wheel that has magnets embedded in it or slots cut into its surface.

- The Process. A small current is passed through the Hall effect sensor. As the target wheel rotates, the magnets (or the absence of metal in the case of slotted wheels) cause the magnetic field around the sensor to fluctuate. When a magnet passes by, the magnetic field strength increases, generating a voltage pulse in the Hall effect sensor. When a non-magnetic area or a slot passes, the magnetic field weakens, and the voltage drops. This creates a series of digital pulses (on/off signals).

- Signal Interpretation. The control module reads these digital pulses. The frequency of the pulses is directly proportional to the rotational speed. A higher pulse frequency means a faster speed. The ECU counts the number of pulses within a specific time frame to calculate the vehicle’s speed. Hall effect sensors are generally more accurate at low speeds compared to inductive sensors.

2.3 Other Types of Speed Sensors.

While reluctance and Hall effect sensors are the most common, other types exist, such as optical sensors that use light beams to detect rotational speed. These are less frequently used in mainstream vehicles for speed measurement but might be found in specific applications.

3. Location, Location, Location: Where are Speedometer Sensors Found?

The location of the speedometer sensor can vary depending on the vehicle’s make, model, and drivetrain configuration. Common locations include:

- Transmission Output Shaft: In many front-wheel drive and rear-wheel drive vehicles, the VSS is located on the transmission’s output shaft. This allows it to directly measure the speed at which the transmission is sending power to the wheels.

- Wheel Hubs: In vehicles equipped with ABS, individual wheel speed sensors are present at each wheel hub. These sensors provide data not only for the ABS but also for the speedometer and other systems.

- Differential: In some rear-wheel drive vehicles, the sensor might be located on the differential housing, measuring the rotation of the pinion gear.

- Transfer Case: For four-wheel drive vehicles, a speed sensor might be located on the transfer case.

4. Why Accurate Speed Readings Matter: The Importance of VSS Data.

The information provided by the speedometer sensor is critical for various vehicle functions:

- Speedometer Display: This is the most obvious function, allowing the driver to monitor the vehicle’s speed.

- Engine Control Unit (ECU): The ECU uses speed data for fuel injection control, ignition timing adjustments, and idle speed regulation. This helps optimize engine performance and fuel efficiency.

- Transmission Control Unit (TCU): In automatic transmissions, the TCU relies on speed information to determine the appropriate time to shift gears. Accurate speed data ensures smooth and timely gear changes.

- Anti-lock Braking System (ABS): ABS uses individual wheel speed sensor data to detect wheel lock-up and modulate brake pressure accordingly. This prevents skidding and helps maintain steering control during hard braking.

- Traction Control System (TCS) and Electronic Stability Control (ESC): These systems use speed sensor data to detect wheel slip and loss of traction. They then apply braking force to individual wheels or reduce engine power to help maintain vehicle stability.

- Cruise Control System: Cruise control uses vehicle speed data to maintain a set speed selected by the driver.

- Navigation Systems: Some navigation systems utilize speed sensor data for more accurate positioning and dead reckoning (estimating position when GPS signal is lost).

5. Troubleshooting Speedometer Sensor Issues: What Can Go Wrong?

Like any other automotive component, speedometer sensors can fail. Here are some common symptoms of a faulty VSS:

- Inaccurate Speedometer Reading: The speedometer might fluctuate erratically, read zero even while driving, or display an incorrect speed.

- Check Engine Light: A faulty VSS can trigger the check engine light, and diagnostic trouble codes (DTCs) related to the speed sensor might be stored.

- Transmission Problems: Issues like harsh shifting, delayed gear changes, or the transmission getting stuck in a particular gear can be caused by incorrect speed data from the VSS.

- ABS and Traction Control Issues: The ABS and TCS/ESC systems might become disabled or function improperly if they are not receiving accurate speed signals.

- Cruise Control Malfunction: The cruise control system might not engage or might disengage unexpectedly due to a faulty VSS.

Potential Causes of VSS Failure:

- Physical Damage: The sensor or its wiring can be damaged by debris, road hazards, or accidents.

- Contamination: Dirt, grease, or other contaminants can interfere with the sensor’s operation.

- Electrical Issues: Problems with the wiring harness, connectors, or the sensor’s internal circuitry can lead to failure.

- Wear and Tear: Over time, the sensor can simply wear out due to constant use and exposure to harsh conditions.

6. Diagnosing and Replacing a Speedometer Sensor: A Mechanic’s Perspective.

Diagnosing a speedometer sensor issue typically involves the following steps:

- Visual Inspection: Check the sensor and its wiring for any signs of physical damage, corrosion, or loose connections.

- Diagnostic Scan: Use a scan tool like those offered by VCCarTool to read any stored diagnostic trouble codes (DTCs) related to the VSS. Common codes include P0500 (Vehicle Speed Sensor A Malfunction) and related codes indicating circuit issues or intermittent faults.

- Live Data Monitoring: Your VCCarTool scan tool can display live data from the speed sensor. Observe the speed readings while the vehicle is stationary and in motion to see if the sensor is providing a consistent and accurate signal.

- Multimeter Testing: Depending on the type of sensor, a multimeter can be used to check the sensor’s resistance, voltage output, or signal frequency. Consult the vehicle’s service manual for specific testing procedures and expected values.

- Oscilloscope Analysis (Advanced): For more in-depth diagnostics, an oscilloscope can be used to visualize the sensor’s output waveform. This can help identify intermittent issues or signal abnormalities.

Replacement Procedure:

If the speedometer sensor is found to be faulty, it will need to be replaced. The general steps involved are:

- Locate the Sensor: Refer to the vehicle’s service manual to identify the exact location of the speed sensor.

- Disconnect Electrical Connector: Carefully disconnect the electrical connector attached to the sensor.

- Remove the Old Sensor: The sensor is usually held in place by a bolt or a retaining clip. Remove the fastener and gently pull out the old sensor.

- Install the New Sensor: Install the new speedometer sensor, ensuring it is properly seated and secured with the bolt or clip.

- Reconnect Electrical Connector: Reattach the electrical connector to the new sensor.

- Test the System: Start the vehicle and use a scan tool (your reliable VCCarTool device) to clear any DTCs. Test drive the vehicle to ensure the speedometer is reading accurately and that other related systems are functioning correctly.

7. VCCarTool: Your Partner in Automotive Excellence.

As experienced auto mechanics and garage owners, you understand the importance of having reliable and efficient tools. VCCarTool is committed to providing you with high-quality diagnostic equipment, including advanced scan tools that allow you to accurately diagnose issues with speedometer sensors and other complex vehicle systems.

Benefits of Choosing VCCarTool:

- Comprehensive Diagnostics: Our scan tools offer in-depth diagnostic capabilities, allowing you to read and clear DTCs, view live data, and perform actuation tests on various vehicle systems, including those related to speed sensing.

- User-Friendly Interface: VCCarTool devices are designed with ease of use in mind, featuring intuitive interfaces and clear instructions, making your diagnostic process smoother and faster.

- Wide Vehicle Coverage: Our tools support a broad range of vehicle makes and models, ensuring you can handle diverse repair jobs in your garage.

- Regular Software Updates: We provide regular software updates to ensure your VCCarTool device stays current with the latest vehicle technologies and diagnostic protocols.

- Exceptional Value: VCCarTool offers professional-grade diagnostic tools at competitive prices, providing excellent value for your investment.

- Dedicated Support: Our team is dedicated to providing you with excellent customer support, assisting you with any questions or technical issues you may encounter.

Ready to elevate your garage’s capabilities and tackle speedometer sensor issues with confidence?

Don’t let diagnostic challenges slow you down. Invest in the power and reliability of VCCarTool diagnostic equipment. Visit our website at vccartool.com or contact us via Whatsapp at +1 (901) 414 – 1927 to learn more and find the perfect tools to meet your needs. Our advanced scan tools will empower you to diagnose and resolve issues like faulty vehicle speed transducers quickly and efficiently, leading to increased customer satisfaction and greater profitability for your business.

Facing speedometer sensor problems or looking to upgrade your diagnostic equipment? Contact VCCarTool today for expert advice and explore our range of high-quality scan tools. Visit vccartool.com or message us on WhatsApp: +1 (901) 414 – 1927 and let us help you enhance your auto repair services.