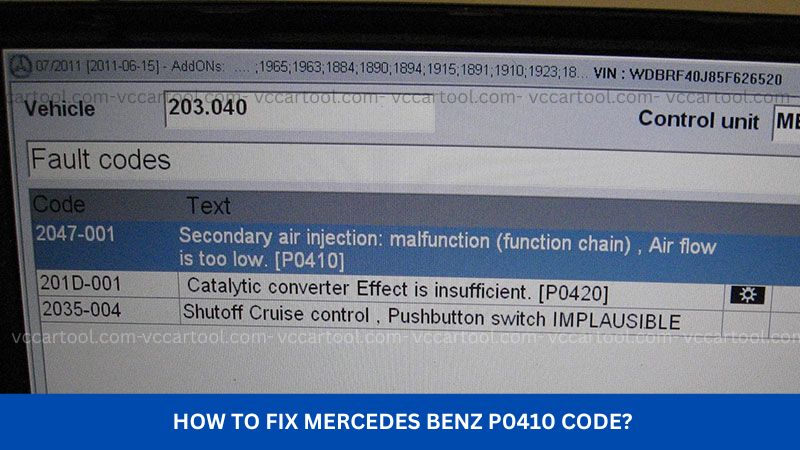

How to Fix Mercedes Benz P0410 Code?

Encountering the Mercedes-Benz P0410 code can be a frustrating experience, particularly for models produced between the late 1990s and 2020. This diagnostic trouble code (DTC) indicates a problem within the secondary air injection system, a vital component for managing emissions during those critical cold start moments. Fear not, as VCCarTool is here to provide you with a comprehensive guide to accurately diagnose and effectively resolve the Mercedes P0410 code, ensuring your vehicle meets emission standards and runs smoothly.

Understanding Mercedes P0410 Code: A Deep Dive

The P0410 code illuminates when your Mercedes-Benz Engine Control Module (ECM) detects an irregularity in the performance or operation of the secondary air injection system. This system is indispensable for minimizing harmful emissions by:

- Introducing fresh air into the exhaust stream to promote the oxidation of unburnt hydrocarbons and carbon monoxide. This chemical process helps convert these pollutants into less harmful substances.

- Accelerating the warm-up process of the catalytic converter. By injecting air, the system helps the catalyst reach its optimal operating temperature more quickly, enabling it to efficiently reduce pollutants.

- Improving overall emissions compliance, especially during the initial engine warm-up phase when emissions are typically higher.

The secondary air system typically engages for a brief period, usually around 40 seconds, immediately after a cold start, specifically when the engine coolant temperature is below approximately 35 degrees Celsius (95 degrees Fahrenheit). During this operation, the ECM expects to see a rise in oxygen levels within the exhaust gases, a confirmation received through the readings from the vehicle’s oxygen (O2) sensors. The absence of this expected oxygen level increase, or other detected malfunctions within the system, will trigger the P0410 code.

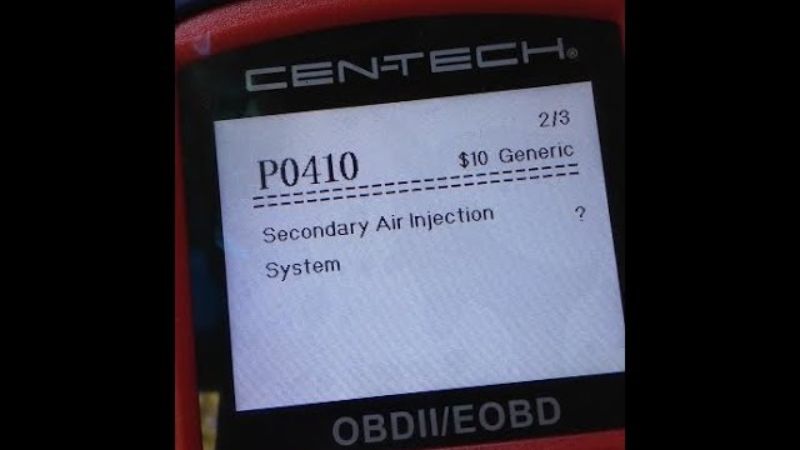

Essential Tools for Diagnosing and Fixing Mercedes P0410

To effectively tackle the P0410 Mercedes-Benz code, having the right tools at your disposal is crucial. VCCarTool recommends the following:

Diagnostic Instruments:

OBD2 Scanner: A reliable OBD2 scanner is your first line of defense. We recommend options like the Autel MaxiCOM series, Launch X431 range, or the iCarsoft MB V3.0, specifically designed for Mercedes-Benz vehicles. These tools allow you to:

-

- Confidently read and verify the presence of the P0410 trouble code.

- Monitor crucial live data parameters related to the engine and emission systems, providing valuable insights into system operation.

- In many cases, activate individual components of the secondary air injection system, such as the secondary air pump and the switchover valve, facilitating targeted testing.

Digital Multimeter: A quality multimeter, such as the Fluke 117 or Klein Tools MM600, is essential for electrical system diagnosis. It will enable you to:

-

- Check the continuity of fuses, ensuring they are intact and conducting electricity properly.

- Test the functionality of relays by verifying coil and contact operation.

- Inspect electrical connections for proper voltage and grounding.

- Measure the resistance of the secondary air pump motor to help determine its internal condition.

Mechanical Aids:

- 12V Power Source: A stable 12V power supply or a fully charged car battery with jumper wires is necessary to directly power the secondary air pump for independent testing.

- Basic Hand Tool Set: A comprehensive set of sockets, ratchets, screwdrivers, and pliers will be required for the physical removal and installation of components like the secondary air pump, relay, and switchover valve.

- Vacuum Pump: A handheld or electric vacuum pump is invaluable for testing the integrity and operation of the switchover valve and for identifying potential vacuum leaks within the system’s hoses.

- Smoke Machine or Leak Detector: For pinpointing elusive air leaks within the various hoses and connections of the secondary air injection system, a smoke machine or electronic leak detector is highly effective. Leaks can prevent the system from functioning correctly.

- Fuse Puller and Spare Fuse: A dedicated fuse puller will safely remove fuses, and having a spare 40-amp fuse (or the correct amperage for your specific model) on hand will allow for quick replacement if a blown fuse is the culprit.

Advanced Diagnostic and Coding Software:

- Mercedes-Specific Diagnostic Software: For more in-depth diagnostics, activation of specific system components, and potential reprogramming, consider utilizing Mercedes-specific software such as XENTRY, Vediamo, or DTS Monaco. These powerful tools, often used by professional Mercedes-Benz technicians, can provide granular control over system testing and allow for resetting the P0410 code after successful repairs. VCCarTool can guide you in selecting compatible software solutions.

Step-by-Step Guide to Resolving the P0410 Code in Your Mercedes-Benz

Follow these systematic steps to diagnose and rectify the P0410 code:

1. Thoroughly Inspect the System Fuse:

- Begin by locating the fuse responsible for the secondary air injection system. This is often a 40-amp fuse and is typically situated in one of the vehicle’s fuse boxes, commonly in the driver’s side compartment near the engine bay. Consult your vehicle’s owner’s manual for the exact location.

- Carefully visually inspect the fuse element for any signs of being blown (a broken or melted wire within the fuse).

- For a definitive check, use your multimeter to test the fuse for continuity. A functional fuse will show continuity (a reading close to 0 ohms).

- If the fuse is blown, replace it with a new fuse of the exact same amperage rating. After replacement, start the vehicle and monitor if the code returns. A recurring blown fuse often indicates a more significant underlying electrical issue that needs further investigation.

2. Conduct a Direct Test of the Secondary Air Pump:

- Locate the secondary air pump. It’s commonly found near the front or left side of the engine compartment, but its exact position can vary depending on your specific Mercedes-Benz model.

- Carefully disconnect the electrical connector leading to the air pump.

- Using your 12V power supply or battery with jumper wires, directly apply 12V to the appropriate terminals of the air pump motor. Refer to your vehicle’s wiring diagram or reliable online resources for the correct terminal identification.

- Observe the pump’s operation. A functioning pump should activate and produce a noticeable airflow. If the pump remains silent or shows no signs of operation, it is likely faulty and will require replacement.

3. Measure the Secondary Air Pump’s Resistance:

- With the electrical connector still disconnected from the air pump, use your multimeter to measure the electrical resistance across the pump motor’s terminals.

- A typically functional air pump motor should exhibit a relatively low resistance value, generally below 1 ohm. However, consult your vehicle’s service manual for the specific resistance range for your pump model.

- If the resistance reading is significantly high (e.g., above 20 ohms or an open circuit), it indicates an internal fault within the pump motor, confirming the need for replacement.

4. Evaluate the Secondary Air Injection System Relay:

- Identify the relay responsible for controlling the secondary air pump. Its location can vary but is often found near the diagnostic port or in a less prominent fuse box. Refer to your vehicle’s wiring diagrams or service information.

- One way to test the relay is to swap it with an identical relay from another non-critical system in your vehicle (if one exists). If the P0410 code disappears and another system now shows a fault, the original relay is likely the issue.

- Alternatively, you can use your multimeter to perform a more thorough test of the relay’s coil and contacts. You should be able to measure resistance across the coil and verify that the contacts close when the coil is energized.

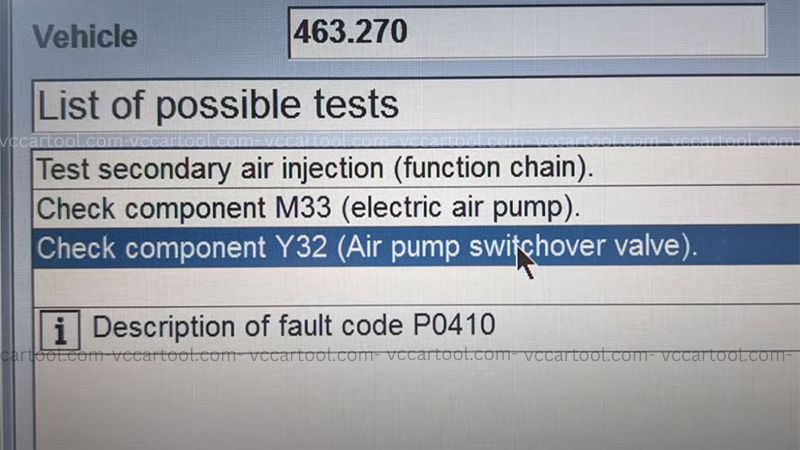

5. Examine the Air Pump Switchover Valve:

- The air pump switchover valve (often referred to as the Y32 valve in Mercedes-Benz documentation) controls the flow of secondary air into the exhaust system.

- With the engine running (and preferably cold), use a compatible scan tool (such as XENTRY, Launch X431, or Autel) to attempt to activate the switchover valve. The scan tool should have an “actuation test” or “component test” function for this purpose.

- While activating the valve, listen carefully for a distinct clicking sound emanating from the valve. This sound typically indicates that the valve’s solenoid is engaging and the valve mechanism is likely operational.

- If no clicking sound is heard during the activation test, first inspect the electrical wiring and voltage supply to the valve. Use your multimeter to check for proper voltage at the valve’s connector when the activation command is sent by the scan tool. If power is present but the valve doesn’t actuate, the valve itself is likely faulty.

6. Carefully Inspect All Hoses and Connections:

- Thoroughly examine all the hoses and connections associated with the secondary air injection system. This includes the air intake hose to the pump, the hoses running from the pump to the switchover valve, and the hoses connecting the valve to the exhaust manifolds.

- Look for any visible signs of cracks, leaks, wear, or disconnections. Pay close attention to areas where hoses bend or connect to other components.

- Ensure that all hose clamps and connections are properly secured and tightened. Even small air leaks can prevent the system from building sufficient pressure and trigger the P0410 code. Using a smoke machine can be highly effective in identifying small, hard-to-find leaks.

Common Resolutions for the P0410 Code

Based on the diagnostic steps, the most common fixes for the P0410 Mercedes-Benz code include:

- Replacing the Faulty Secondary Air Pump: If your testing indicates a defective air pump, installing a new, genuine Mercedes-Benz replacement part (ensure you verify the correct part number for your specific engine model, e.g., A0001404285 for some M113 engines) is usually the necessary solution. Carefully disconnect the old pump’s hoses and wiring, remove it from its mounting, and install the new pump, ensuring all connections are secure. After replacement, clear the P0410 fault code using your OBD2 scanner and perform a test drive.

- Replacing the Malfunctioning Air Pump Switchover Valve: If the Y32 valve is determined to be faulty, replacing it with a new unit (e.g., Mercedes-Benz part #A0005003201 for many models, but always confirm the correct part for your vehicle) is required. Locate the valve, disconnect its electrical wiring and vacuum hoses, remove the old valve, and install the new one, ensuring all connections are properly made.

- Repairing Wiring Issues: If your inspection reveals damaged wiring or corroded electrical connectors within the secondary air injection system’s circuitry, carefully repair or replace the affected wiring and connectors. Ensure proper continuity between all components and the ECM.

- Replacing the Defective Relay: If the secondary air pump relay is found to be faulty, installing a new relay of the correct type and rating should restore the system’s operation.

Important Considerations for Mercedes-Benz Owners

- The P0410 issue has been noted to be relatively common in Mercedes-Benz models spanning from approximately 1997 to 2020.

- Some Mercedes-Benz owners have reported success in temporarily resolving the P0410 code by simply cleaning the air intake pathway leading to the secondary air pump, removing any accumulated debris that might be obstructing airflow. However, this is often a temporary fix if the pump or other components are failing.

- It’s important to be aware that even after replacing the secondary air pump, if other components within the system (such as the switchover valve or hoses) are also faulty, the P0410 code may reappear. A thorough diagnosis of the entire system is crucial.

- If you are uncomfortable performing these DIY diagnostic and repair procedures, or if the P0410 code persists after your efforts, it is highly recommended to seek professional diagnostic services from a qualified automotive technician specializing in Mercedes-Benz vehicles.

Conclusion: Resolving Your Mercedes-Benz P0410 Code

The P0410 code in your Mercedes-Benz is a strong indicator of a problem within the secondary air injection system. By systematically following the diagnostic steps outlined in this comprehensive guide, you can confidently identify the root cause of the issue, whether it’s a failing air pump, a faulty switchover valve, an electrical problem, or a damaged hose. Armed with the right tools and a methodical approach, you can often resolve the P0410 code yourself, ensuring your Mercedes-Benz operates cleanly and efficiently.

If you find yourself needing expert assistance with diagnosing, coding, or programming your Mercedes-Benz vehicle, don’t hesitate to reach out to the skilled professionals at VCCarTool. We specialize in providing advanced automotive solutions for Mercedes-Benz and are here to support you. Contact us today via Whatsapp at +1 (901) 414 – 1927 or visit our website at vccartool.com for professional guidance and access to high-quality diagnostic tools. Let us help you keep your Mercedes-Benz performing at its best.